Choice of plastic

-

Hello, I am in the process of putting the benchtop flow battery together. It is a bit difficult to get the exact materials.

My knowledge of plastic and its chemistry is somewhat limited.I'm interested in why the specific plastics were used and which ones could be used as substitutes.

What criteria need to be considered?

What has already been tested?

What else could be tested? -

I'm also interested in this topic. Polypropylene is not a trouble-free material. There are some other filaments classified as chemically resistant (https://help.prusa3d.com/filament-material-guide). Is PP the only suitable option?

-

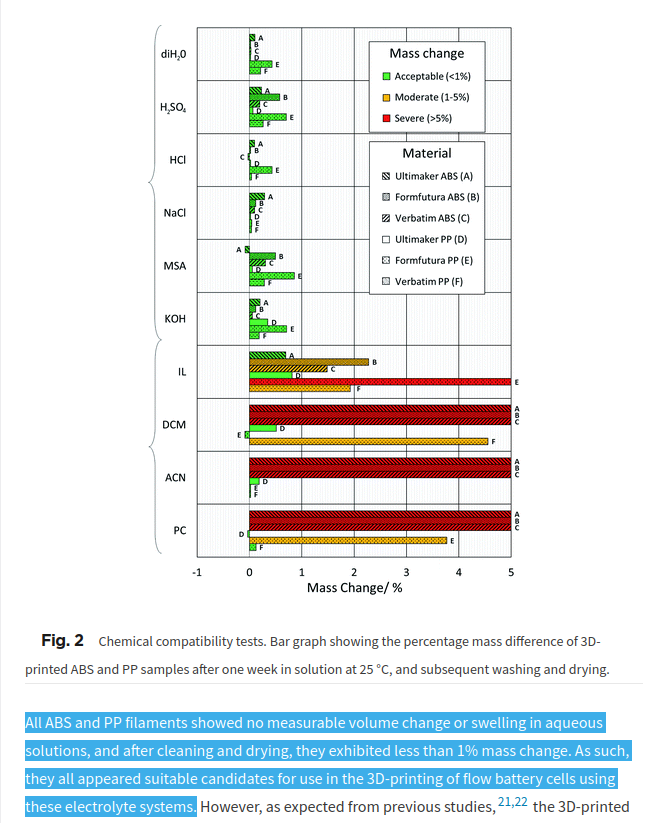

Great questions - our starting point was this paper, there are a lot of citations there to other papers where FDM materials have been tested in different chemical solutions. They have a discussion on why they chose ABS and PP as materials for testing flow battery chemistries with, they mention PETG as an option, but don't test it (and I don't think it would work for us right now). Fig. 2 is very relevant:

For the chemistries we look at now - transition metal halides - the results for DI water, sulfuric acid, hydrochloric acid, and sodium chloride salt solution are probably the most relevant, given the pH and ions present in solution.

In their paper, they struggle to print sufficiently watertight PP prints, but they are able to get good enough ABS prints. They test the most common vanadium-based electrolyte in their setup, which is acidic, and chemically compatible with ABS. However, we specifically don't want to start with vanadium since it is relatively expensive, hard to get, and toxic - with respect to our chosen starting chemistry of zinc-iodide.

The tradeoff here is - when charged, the zinc-iodide chemistry's positive electrolyte contains iodine, usually in the form of the triiodide complex.

Iodine and triiodide have very peculiar chemical compatibility requirements, and they are NOT compatible with ABS or PETG, so we have to use PP. If we are able to develop an alternative chemistry that is available, cheap, and safe to work with, then ABS or PETG may be an option in the future.

We have designed our cell in such a way that we seem to be able to get "tight" enough prints to have leakage not be an issue in our benchtop tests. However, we are only printing cells with a 2 cm2 active area, whereas the paper above is testing 25 cm2. Time will tell if our process can scale up - I'm right now in the process of designing a flow frame for a 175 cm2 flow frame for our first larger-format cell, and the idea is to FDM print this at first.

In "real" industry applications, the flow frames of a flow battery are, to my knowledge, injection or compression molded. PP and HDPE are common polymers for this, and I have heard of PVC also, for particular chemistries.