General Discussion

General discussion for the Flow Battery Research Collective

This category can be followed from the open social web via the handle general-discussion@fbrc.nodebb.com

40

Topics

512

Posts

-

New member introduction thread!

Watching Ignoring Scheduled Pinned Locked Moved0 Votes55 Posts7k Views -

You Tuber Video on an open source all Iron battery

Watching Ignoring Scheduled Pinned Locked Moved1 Votes1 Posts20 Views -

1 Votes6 Posts80 Views

-

My Suction Luer Lock

Watching Ignoring Scheduled Pinned Locked Moved2 Votes3 Posts54 Views -

New ion exchange membrane recipe using water softener resin and PVC cement

Watching Ignoring Scheduled Pinned Locked Moved0 Votes10 Posts133 Views -

Using cnc router cut PVC foam boards as cell frame

Watching Ignoring Scheduled Pinned Locked Moved0 Votes1 Posts18 Views -

Preprint from Forner-Cuenca group: RfbFoam: An open-source framework for porous electrode modeling in redox flow batteries

Watching Ignoring Scheduled Pinned Locked Moved0 Votes1 Posts65 Views -

1 Votes66 Posts8k Views

-

Life Cycle Assessment (LCA) for the FBRC redox-flow battery

Watching Ignoring Scheduled Pinned Locked Moved0 Votes6 Posts499 Views -

Following your documentation – feedback & questions

Watching Ignoring Scheduled Pinned Locked Moved 1

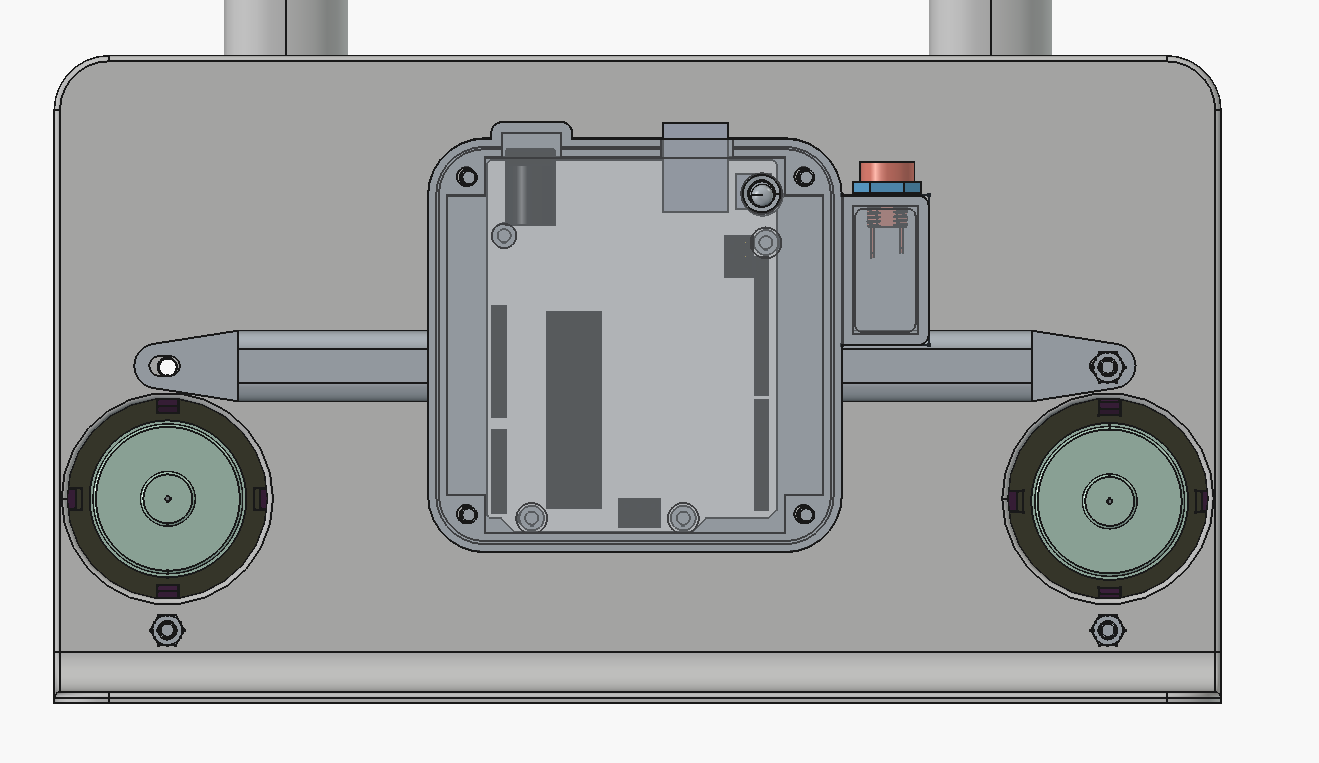

3 Votes65 Posts8k Views

1

3 Votes65 Posts8k Views -

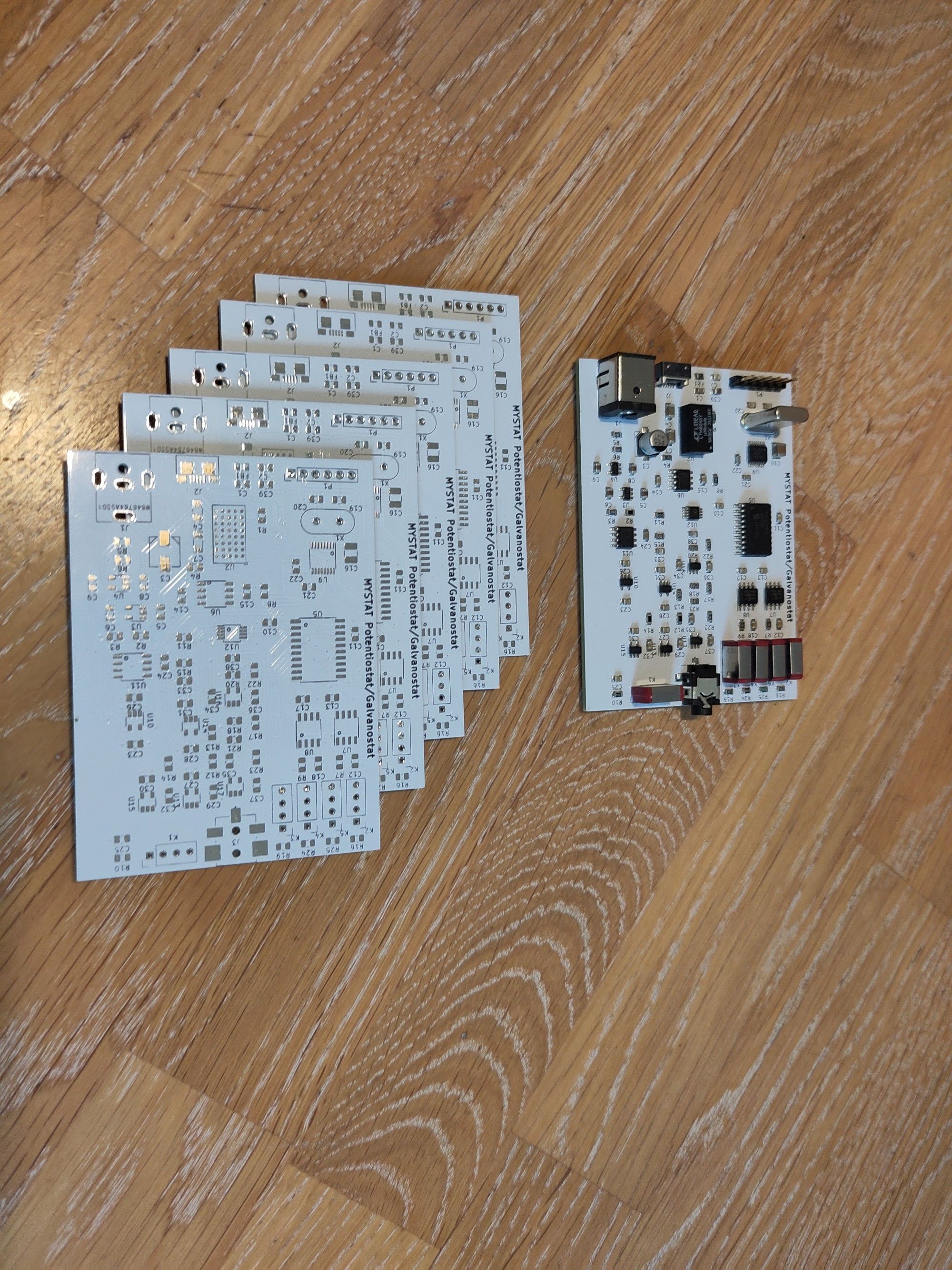

MyStat control software refactor

Watching Ignoring Scheduled Pinned Locked Moved1 Votes3 Posts346 Views -

3 Votes61 Posts7k Views

-

Tygon chemical for sale

Watching Ignoring Scheduled Pinned Locked Moved2 Votes9 Posts584 Views -

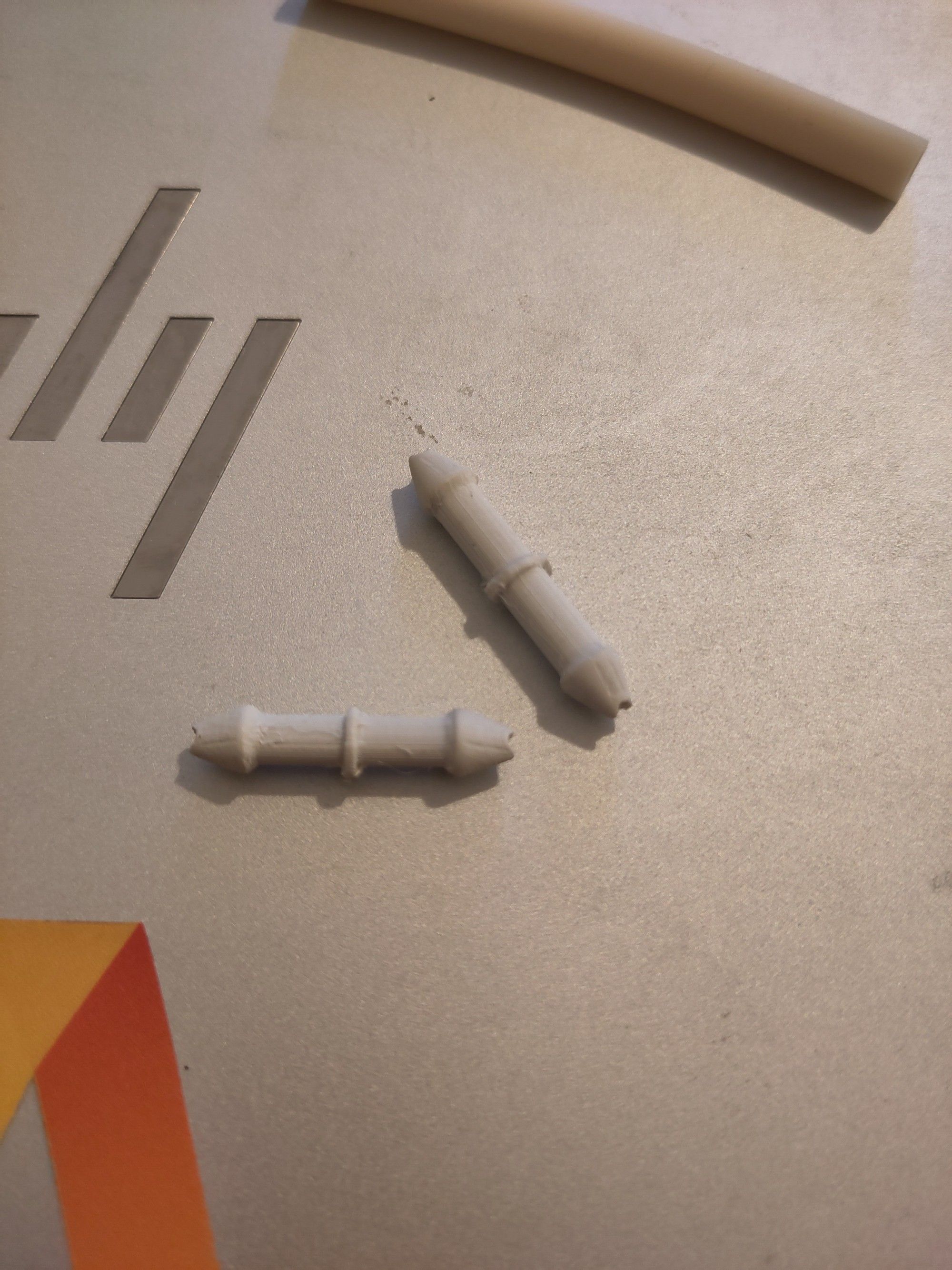

Thin sleeves to insulate screws (no more tape)

Watching Ignoring Scheduled Pinned Locked Moved 1

3 Votes7 Posts679 Views

1

3 Votes7 Posts679 Views -

Youtube Video from Undecided has some interesting new info on Zinc batteries

Watching Ignoring Scheduled Pinned Locked Moved0 Votes1 Posts104 Views -

3 Votes4 Posts417 Views

-

Separator material

Watching Ignoring Scheduled Pinned Locked Moved1 Votes16 Posts1k Views -

This topic is deleted!

Watching Ignoring Scheduled Pinned Locked Moved1 Votes3 Posts8 Views -

Theoretical Practical tank size limit

Watching Ignoring Scheduled Pinned Locked Moved0 Votes15 Posts1k Views -

2 Votes14 Posts1k Views