Designing the large-format cell

-

@wordmark@mas.to said in Designing the large-format cell:

Previous thought: so u say this cell makes O2 and H2 going out from separate outlets?

No, that is not at all the intended operation, but it is a possible unintended side reaction if something goes wrong or is poorly designed/outside the operating mode.

@wordmark@mas.to said in Designing the large-format cell:

What volts amps will your stack require? Production costs per stack?

@wordmark@mas.to said in Designing the large-format cell:

what are the properties for such a battery? (How does it compare to a 48V 14kWh #LiFePo4? (Which can burn down houses if cells are not high quality)

We are very far from having a datasheet on such an RFB, as we are still very much in the R&D phase, but there are some datasheets out there from commercial companies which could give you an idea, but generally RFBs don't make sense below 10 kWh in size because of their size and requirement of centrifugal pumps.

We have a FAQ that might answer some of your questions here.

This post is deleted! -

@wordmark@mas.to said in Designing the large-format cell:

Previous thought: so u say this cell makes O2 and H2 going out from separate outlets?

No, that is not at all the intended operation, but it is a possible unintended side reaction if something goes wrong or is poorly designed/outside the operating mode.

@wordmark@mas.to said in Designing the large-format cell:

What volts amps will your stack require? Production costs per stack?

@wordmark@mas.to said in Designing the large-format cell:

what are the properties for such a battery? (How does it compare to a 48V 14kWh #LiFePo4? (Which can burn down houses if cells are not high quality)

We are very far from having a datasheet on such an RFB, as we are still very much in the R&D phase, but there are some datasheets out there from commercial companies which could give you an idea, but generally RFBs don't make sense below 10 kWh in size because of their size and requirement of centrifugal pumps.

We have a FAQ that might answer some of your questions here.

This post is deleted! -

Would spraying a solvent diluted silicone caulking form a electrolyte resistant gasket surface?

Edit; this was after reading on the Cricut cut silicone sheet. After reading on the electrolyte a bit more, it seems not even silicone is a good gasket material for I3- ???

-

Would spraying a solvent diluted silicone caulking form a electrolyte resistant gasket surface?

Edit; this was after reading on the Cricut cut silicone sheet. After reading on the electrolyte a bit more, it seems not even silicone is a good gasket material for I3- ???

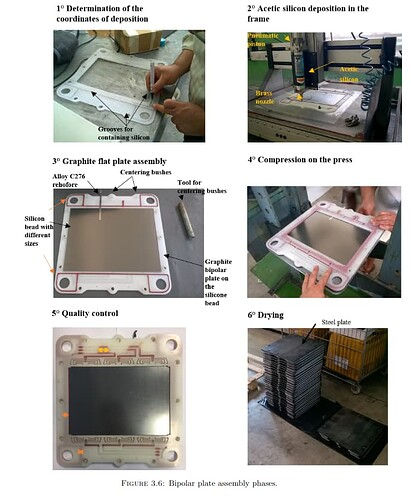

@DDM I don't know if this would work. We can try it! The problem would be spreading this evenly enough and making sure it cures properly. While silicone doesn't work well if it is constantly getting put under pressure (like in a peristaltic pump), it does fine as gasketing material. Note that it's not like the material "fails" it just leaks I2 through time because of diffusion, this diffusion also makes the gaskets warp a bit.

-

@DDM I don't know if this would work. We can try it! The problem would be spreading this evenly enough and making sure it cures properly. While silicone doesn't work well if it is constantly getting put under pressure (like in a peristaltic pump), it does fine as gasketing material. Note that it's not like the material "fails" it just leaks I2 through time because of diffusion, this diffusion also makes the gaskets warp a bit.

@danielfp248 The evenness of the coating could be achieved by setting up a parameter controlled spraying process, which is not really hard to do and can utilize cheap tools (HVLP spray gun and such).

Alternatively I can see silicone dipping working as well, but that would require some tooling.

I've got experience in developing equipment for commercial application of such silicone coatings, and I think I could add some more consulting/value in this project. Is there a way to have direct contact, I tried finding email addresses on chemisting.com but failed, luckily I found the forum. If this turns out well, I might equip a large yacht with this DIY technology as the main energy storage system, including for it's hybrid diesel/electric propulsion. -

@danielfp248 The evenness of the coating could be achieved by setting up a parameter controlled spraying process, which is not really hard to do and can utilize cheap tools (HVLP spray gun and such).

Alternatively I can see silicone dipping working as well, but that would require some tooling.

I've got experience in developing equipment for commercial application of such silicone coatings, and I think I could add some more consulting/value in this project. Is there a way to have direct contact, I tried finding email addresses on chemisting.com but failed, luckily I found the forum. If this turns out well, I might equip a large yacht with this DIY technology as the main energy storage system, including for it's hybrid diesel/electric propulsion.@DDM Sounds very interesting, if you can give it a try let us know if it works well! A potential problem I see is also the wetting of polypropylene, I don't know how well these silicones wet it, polypropylene is notoriously hard to glue or apply stuff to.

-

There is flame activation, and even a combination that deposits silicone oxides: https://www.bohle.com/bx-NL/Pyrosil-Professionele-set/BO5209491

But I'm not sure if that is even needed; the layer will stay stuck for (careful) assembly and perform the sealing duty as it is clamped. Serviceability will be zero, after disassembly the old coating will probably be worthless and a new coating should be applied.

I don't have the materials and setup currently to perform tests.Is there a way to discuss some things directly without filling this forum with a slow-chat?

-

@Vorg First we will make sure the design doesn't leak with current silicone gaskets. Once we have that I can send you a message and we can talk a bit more about how it would work with a silicone sealant.

-

@Vorg First we will make sure the design doesn't leak with current silicone gaskets. Once we have that I can send you a message and we can talk a bit more about how it would work with a silicone sealant.

@danielfp248 yes, except vorg is another user

-

@danielfp248 yes, except vorg is another user

@DDM Lol, sorry, I will message you both.

-

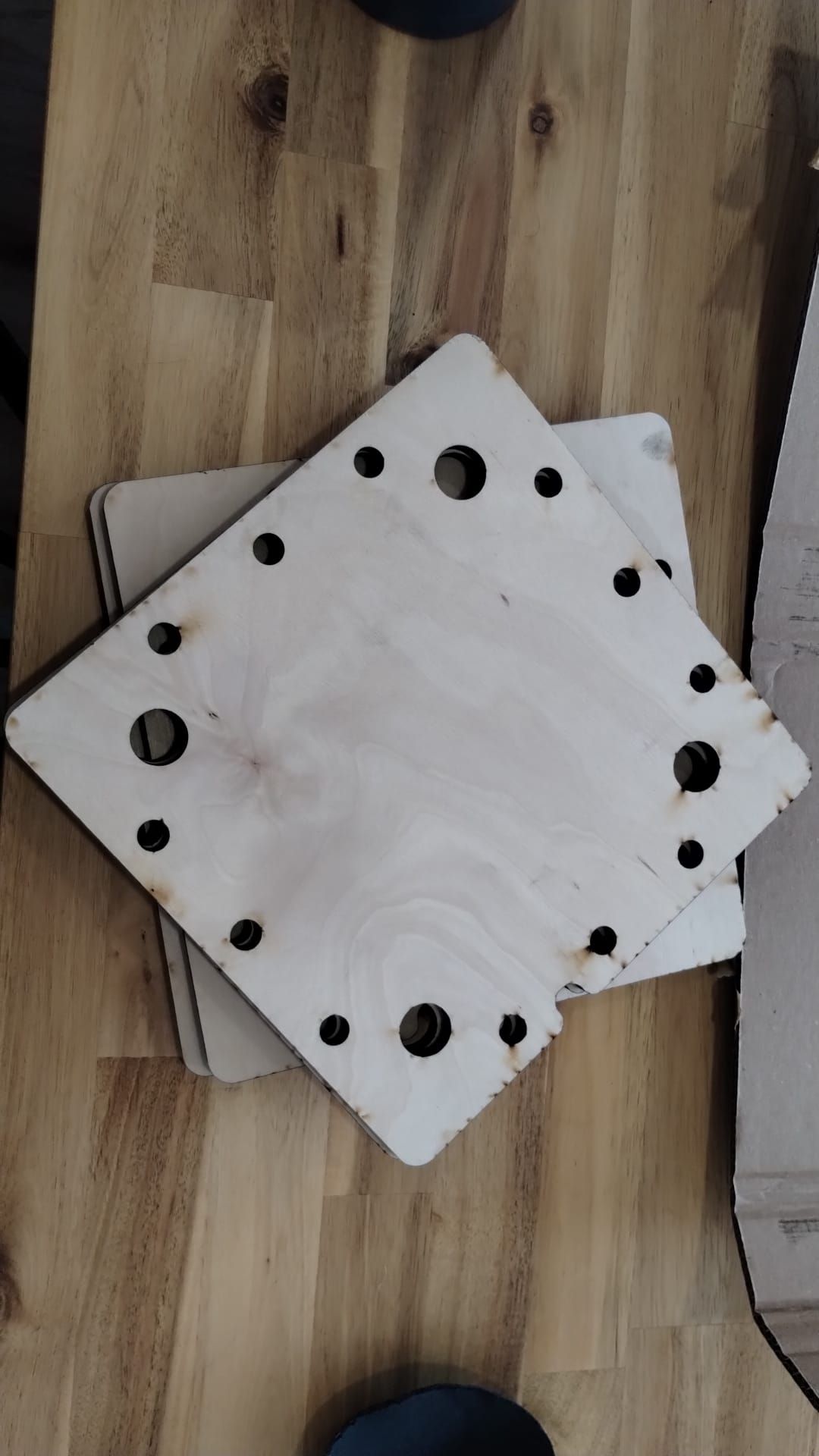

I also just got birchwood endplates for the first test of the large scale design. These are 1.8cm thick, so stiff enough to be able to seal the cell in theory. Since there is no chemical contact with the endplate, we shouldn't have any problem using this material. I will get brass current collectors next week - Xometry just shipped them to me - and will then proceed with the first test.

-

@danielfp248 congrats! Is this plywood and is there any reason you could not manufacture this using regular woodworking tools, like a table saw and drill press? (Which I fortunately have at home

-

@danielfp248 congrats! Is this plywood and is there any reason you could not manufacture this using regular woodworking tools, like a table saw and drill press? (Which I fortunately have at home

@sepi It is not plywood it is birchwood (people who did the laser cutting didn't have plywood). You can manufacture this with normal wood working tools, I don't have any so it was just easier to order it. Important thing is that hole locations are correct and the wood be very flat. You definitely need a planer to achieve that.

-

If it's solid wood, there is a high chance that it will warp with changes in temperature and/or humidity. I guess it is some kind of plywood made from birch wood. Plywood is much less prone to warping due to the aforementionned external factors. In the end things might be different since the plates will be under pressure. I'm wondering if a structure a bit similar to what you did for the PLA endplates in the small battery might work. That's off course only if you run into trouble with your current, simple design.

-

I just put together the first large scale cell and did a test with tap water recirculation to test if the geometry would work with no leaks. I didn't use any grafoil but just the bare brass current collectors, since I'm not doing any electrochemical testing right now.

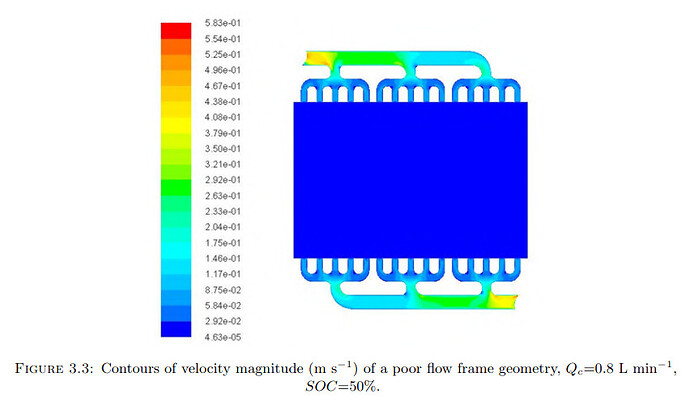

There was a significant leak from one of the input ports as the pressure required to flow through the flow frame geometry was too high, but there were no leaks through the gaskets. We are going to be modifying the flow frame geometry to be the simplest possible, similar to the small scale kit. This way we can make sure we have a design that can flow at the lowest possible pressure and then we can scale complexity as required later on to improve shunt currents. We might also add barbs to the input ports to prevent this sort of leaking. We'll keep you posted on our progress!

Also, the wood did not warp on compression!

-

I'm 99% sure this is not possible, but maybe tossing it out there would give someone an idea for another direction to look. This problem of a shunt current makes my envision some sort of FET like object with a passage between source and drain to allow fluid to flow through it while a "gate voltage" pinches off current flow through it.

I know, crazy, but maybe now that it's out there, the thought will stop bouncing around in my head

-

I'm 99% sure this is not possible, but maybe tossing it out there would give someone an idea for another direction to look. This problem of a shunt current makes my envision some sort of FET like object with a passage between source and drain to allow fluid to flow through it while a "gate voltage" pinches off current flow through it.

I know, crazy, but maybe now that it's out there, the thought will stop bouncing around in my head

-

I just put together the first large scale cell and did a test with tap water recirculation to test if the geometry would work with no leaks. I didn't use any grafoil but just the bare brass current collectors, since I'm not doing any electrochemical testing right now.

There was a significant leak from one of the input ports as the pressure required to flow through the flow frame geometry was too high, but there were no leaks through the gaskets. We are going to be modifying the flow frame geometry to be the simplest possible, similar to the small scale kit. This way we can make sure we have a design that can flow at the lowest possible pressure and then we can scale complexity as required later on to improve shunt currents. We might also add barbs to the input ports to prevent this sort of leaking. We'll keep you posted on our progress!

Also, the wood did not warp on compression!

@danielfp248 congrats, that sounds like a small win already! I'm looking forward to reading about your progress!

-

I'm 99% sure this is not possible, but maybe tossing it out there would give someone an idea for another direction to look. This problem of a shunt current makes my envision some sort of FET like object with a passage between source and drain to allow fluid to flow through it while a "gate voltage" pinches off current flow through it.

I know, crazy, but maybe now that it's out there, the thought will stop bouncing around in my head

@Vorg said in Designing the large-format cell:

I'm 99% sure this is not possible, but maybe tossing it out there would give someone an idea for another direction to look. This problem of a shunt current makes my envision some sort of FET like object with a passage between source and drain to allow fluid to flow through it while a "gate voltage" pinches off current flow through it.

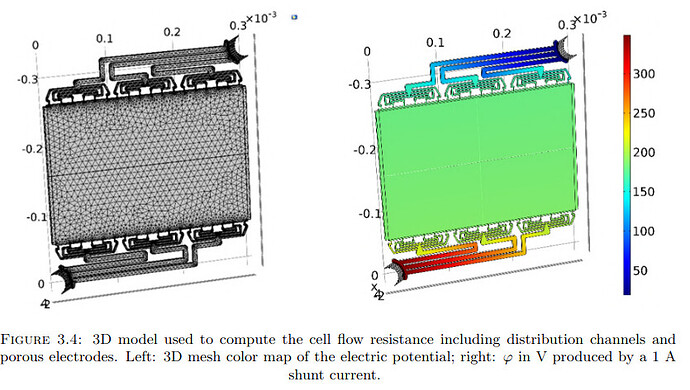

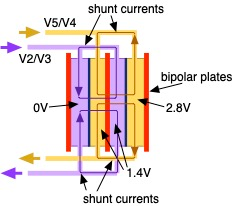

There are A LOT of different approaches out there for dealing with shunt currents---right now the approach I'm taking is "we'll cross that bridge when we come to it"---and the "long manifold" approach that balances the overall sum of [pressure drop] + [shunt current losses] seems like a promising passive approach, ie. not requiring moving parts or actively driven auxiliary electrodes. It is the most common approach I've seen commercial entities take, but that's not to say it's the best.

Like you describe, an "ionic diode" of sorts would be ideal!

There are approaches where people have passed "protective" currents through the manifold to cancel out the shunt currents, but it is an active control method if I understand correctly.

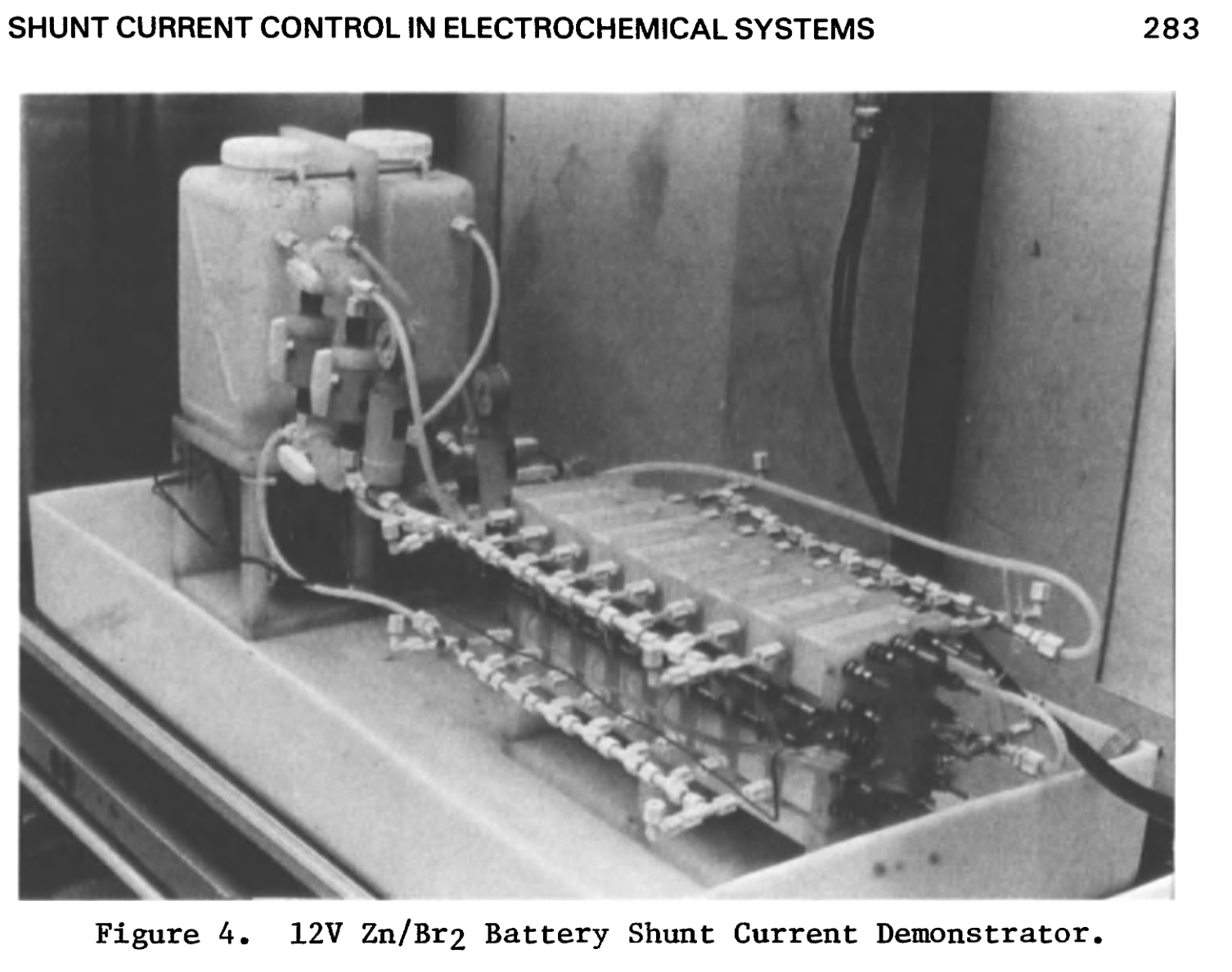

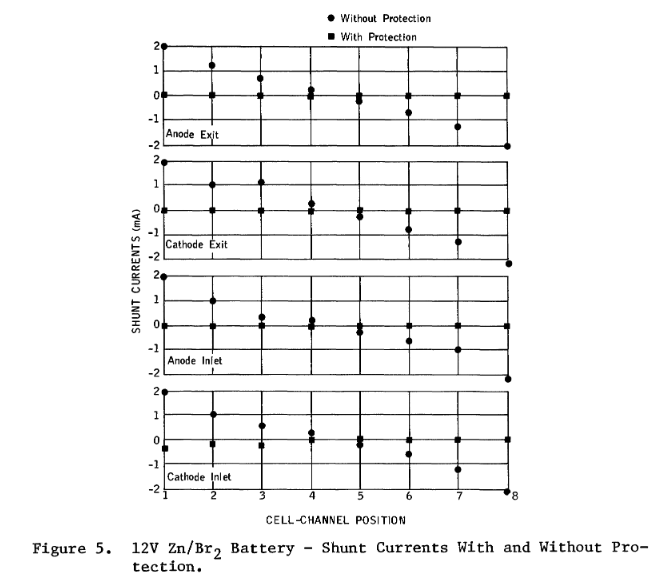

The shunt current protective currents were then passed through the protective electrodes inserted at the first and last channel/manifold node point connections. The shuntage currents through the channels were reduced/eliminated. The effects with the passage of protective current for a charge mode are shown in Figure 5. Similar data at other conditions are given in Zahn, Grimes, and Bellows, 1980.

Source: White, R.E. (1984). Electrochemical Cell Design, Springer US, Boston, MA

Chapter: SHUNT CURRENT CONTROL METHODS IN ELECTROCHEMICAL SYSTEMS - APPLICATIONS

Patrick G. Grimes and Richard J. Bellows

Advanced Energy Systems Laboratory

Exxon Research & Engineering Company Linden, New Jersey 07036 -

K kirk referenced this topic on

K kirk referenced this topic on