Towards a working system

-

Since our design prevents direct contact with the current collector, almost any metal should work. you could even use aluminum foil if you really don't want to machine anything (although I wouldn't recommend it! lol). Bear in mind that the graphite foil is not impervious to the electrolyte, it diffuses slowly through it, so if you have highly charged electrolyte some reactivity with the current collector will happen through time (across weeks of cycling).

There is a paper on creating an electrode using graphoil and wax that might be much better (https://chemistry-europe.onlinelibrary.wiley.com/doi/abs/10.1002/slct.202103996). I will probably get a rosin press to test this and construct some better quality electrodes for our kits.

-

@danielfp248 that makes a lot of sense. Being a complete newb, I slowly gather an understanding of the individual components of the cell.

-

Thanks Kirk!

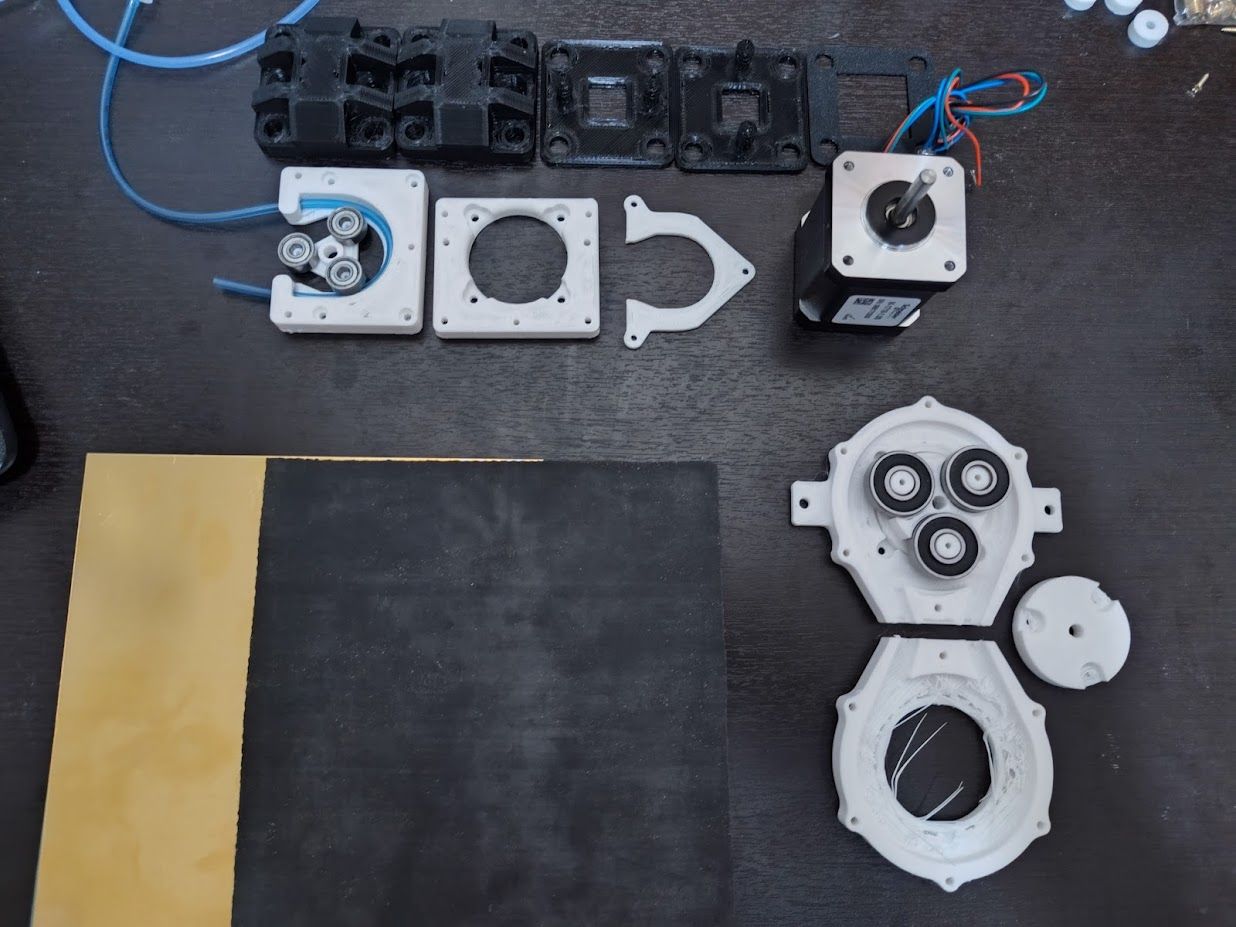

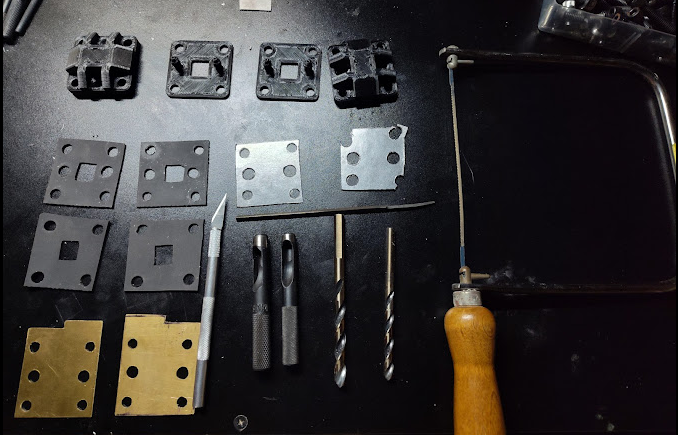

Here's a brief update. I've decided to see how I can make this with the simplest of tools (i.e., thinking if one didn't have access to CNC or a manual mill).

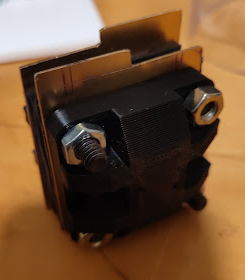

I've found that using hand files, drill bits, and a coping saw (24 tpi bimetal blade), I can make the current collectors of 1 mm brass with a little elbow grease (WD-40 made the cutting substantially easier). My hacksaw was not a great choice for the thin brass.

In addition, by printing the gasket template for a guide, and then cutting the holes and cavity with some cheap circular punches and an x-acto knife, I got some jenky gaskets.

Not the prettiest, but I'll refine my technique as needed. I'm eager to get to leak testing to see whether my printing settings are OK.

Also, should I have made this a blog post? Happy to delete and move if that's better.

@quinnale this look great!!

@quinnale said in Towards a working system:

In addition, by printing the gasket template for a guide, and then cutting the holes and cavity with some cheap circular punches and an x-acto knife, I got some jenky gaskets.

I've done similar, it's definitely possible as you've shown!

@quinnale said in Towards a working system:

Also, should I have made this a blog post? Happy to delete and move if that's better.

Oh no worries there, I made that category in part as a container for Daniel's blog - WordPress and our forum software can interact (via ActivityPub), so that we can reference and comment on his (and other people's) longform WordPress posts directly here in the forum, like what's happening here.

@quinnale said in Towards a working system:

Also, here's an update on the 3D-printed pump! Been running it for about an hour, no issues. Unlisted Youtube video . If anyone is curious I can provide more details. Gonna try run it to death, see if the plastic or the tubing fails first.

That's awesome! Having another pump option besides only Kamoer would be great (esp. an open-source one!). It's this pump you've used?

@sepi said in Towards a working system:

eing a complete newb, I slowly gather an understanding of the individual components of the cell.

Glad to hear it, that's one of the whole points of this forum!

-

K kirk referenced this topic on

K kirk referenced this topic on

-

@quinnale this look great!!

@quinnale said in Towards a working system:

In addition, by printing the gasket template for a guide, and then cutting the holes and cavity with some cheap circular punches and an x-acto knife, I got some jenky gaskets.

I've done similar, it's definitely possible as you've shown!

@quinnale said in Towards a working system:

Also, should I have made this a blog post? Happy to delete and move if that's better.

Oh no worries there, I made that category in part as a container for Daniel's blog - WordPress and our forum software can interact (via ActivityPub), so that we can reference and comment on his (and other people's) longform WordPress posts directly here in the forum, like what's happening here.

@quinnale said in Towards a working system:

Also, here's an update on the 3D-printed pump! Been running it for about an hour, no issues. Unlisted Youtube video . If anyone is curious I can provide more details. Gonna try run it to death, see if the plastic or the tubing fails first.

That's awesome! Having another pump option besides only Kamoer would be great (esp. an open-source one!). It's this pump you've used?

@sepi said in Towards a working system:

eing a complete newb, I slowly gather an understanding of the individual components of the cell.

Glad to hear it, that's one of the whole points of this forum!

@kirk Yes, that is the pump.

I should add a disclaimer that I still consider it early tests but if anyone wants to try some of these builds alongside me, I'm happy to share notes! Although it works, the sizing of the cavity for the tubing isn't quite ideal. The tube tends to twist. So I have a bit of refinement on either tubing choice or modifying the build files. Or trying other existing setups out there.

Thanks for the other notes! I continue, just slowly.

-

Small updates. I cheated and moved the cell the lab I work in for leak testing while I seek time to explore pumps. My PLA flow frames leaked, moving on from that.

I got excellent prints with high impact polystyrene (HIPS) and have been flowing DI water through the system without leaks. Admittedly, I used a Bambu system for this one while I am trying to get reasonable prints on my Ender3. I intend to test neutral-to-alkaline systems using HIPS. Frankly no idea if it's compatible with the iodine / zinc chemistry.

I'm using 0.187" ID silicone tubing. I had to drill a 10 mm hole in the backing plate to make sure the tubing fit. I guess it has thick walls but BPT seems to be similar thickness?

I've also been using imperial hardware (1/4-20 bolts), which the holes are slightly undersized for. Not big issues, just consequences of my choices.

I employed PV-15 graphite instead of grafoil. I've found this stuff difficult to work with due to it's fragility around the bolt holes. I'll probably bend and order grafoil soon.

On to printing polypropylene! And testing ferri/ferrocyanide in the HIPS cell.

-

@quinnale said in Towards a working system:

I cheated and moved the cell the lab I work in for leak testing while I seek time to explore pumps. My PLA flow frames leaked, moving on from that.

Your cell looks quiet good. Damned that it is leaking. I guess this is the most critical test what we are all afraid of. But it has to be done, otherwise we will have the chaos later on. Good luck with your PP prints, it is really a "fun" ...

I've also been using imperial hardware (1/4-20 bolts), which the holes are slightly undersized for. Not big issues, just consequences of my choices.

One option is to use the FreeCAD source and adjust the diameters accordingly.

-

Small updates. I cheated and moved the cell the lab I work in for leak testing while I seek time to explore pumps. My PLA flow frames leaked, moving on from that.

I got excellent prints with high impact polystyrene (HIPS) and have been flowing DI water through the system without leaks. Admittedly, I used a Bambu system for this one while I am trying to get reasonable prints on my Ender3. I intend to test neutral-to-alkaline systems using HIPS. Frankly no idea if it's compatible with the iodine / zinc chemistry.

I'm using 0.187" ID silicone tubing. I had to drill a 10 mm hole in the backing plate to make sure the tubing fit. I guess it has thick walls but BPT seems to be similar thickness?

I've also been using imperial hardware (1/4-20 bolts), which the holes are slightly undersized for. Not big issues, just consequences of my choices.

I employed PV-15 graphite instead of grafoil. I've found this stuff difficult to work with due to it's fragility around the bolt holes. I'll probably bend and order grafoil soon.

On to printing polypropylene! And testing ferri/ferrocyanide in the HIPS cell.

@quinnale Congratulations on the test! I mean, no cheating in open source! Any use of our developments we consider a success. Printing PP without leaks often requires a bit of tuning, but it is achievable. Oftentimes using a bit of overflow and reducing the line thickness to be slightly below nozzle diameter can do the trick. In any case, very happy to hear that you were able to get it working without leaks using HIPS, if it is compatible with the chemistry you will be studying, then that is great.

-

Small updates. I cheated and moved the cell the lab I work in for leak testing while I seek time to explore pumps. My PLA flow frames leaked, moving on from that.

I got excellent prints with high impact polystyrene (HIPS) and have been flowing DI water through the system without leaks. Admittedly, I used a Bambu system for this one while I am trying to get reasonable prints on my Ender3. I intend to test neutral-to-alkaline systems using HIPS. Frankly no idea if it's compatible with the iodine / zinc chemistry.

I'm using 0.187" ID silicone tubing. I had to drill a 10 mm hole in the backing plate to make sure the tubing fit. I guess it has thick walls but BPT seems to be similar thickness?

I've also been using imperial hardware (1/4-20 bolts), which the holes are slightly undersized for. Not big issues, just consequences of my choices.

I employed PV-15 graphite instead of grafoil. I've found this stuff difficult to work with due to it's fragility around the bolt holes. I'll probably bend and order grafoil soon.

On to printing polypropylene! And testing ferri/ferrocyanide in the HIPS cell.

@quinnale said in Towards a working system:

I got excellent prints with high impact polystyrene (HIPS) and have been flowing DI water through the system without leaks. Admittedly, I used a Bambu system for this one while I am trying to get reasonable prints on my Ender3.

Thanks for documenting this! Looks awesome so far. Open question to you and others, especially about alkaline electrolytes. All of the easily printable polymers I've worked with have pretty poor resistance to highly basic solutions. PP has been the best of both worlds but it's hard to say it's easy to print with. Is HIPS working well? Is it easier to print with and still able to handle ~20wt% hydroxide solutions?

-

@quinnale said in Towards a working system:

I got excellent prints with high impact polystyrene (HIPS) and have been flowing DI water through the system without leaks. Admittedly, I used a Bambu system for this one while I am trying to get reasonable prints on my Ender3.

Thanks for documenting this! Looks awesome so far. Open question to you and others, especially about alkaline electrolytes. All of the easily printable polymers I've worked with have pretty poor resistance to highly basic solutions. PP has been the best of both worlds but it's hard to say it's easy to print with. Is HIPS working well? Is it easier to print with and still able to handle ~20wt% hydroxide solutions?

@muntasirms Absolutely! A bunch of other great documentation on here, wanted to try to my part.

I have a colleague who uses HIPS exclusively in strong alkaline systems. Significantly easier to print than PP from my limited experience.

It's not pure polystyrene (which is great for alkaline), but the additive(s) don't seem to affect their tolerance too much.

I'll keep you posted on compatibility as I test these systems! Not sure how long the parts will last yet.