How should we control the centrifugal pumps? TRIAC/thyristor etc? Need help from controls/electrical people

-

@kirk from my point of view controlling the speed of this particular motor would be rather hard. I am not big expert on motors, so I would need to consult it.

Nevertheless I would ask a question: how much power and what RPM we really need in that project - Using 3phase AC motors is of course an option, but it is probably an overkill, maybe we can easily use even steppers like NEMA23, which are quite cheap, and we can really precisely control the speed

The NEMA was used for example in Recyclebot:

https://www.appropedia.org/Recyclebot

And there is an Arduino code:

https://codeberg.org/309631/recyclebotV6.2With NEMA we do not need much power, as well as we do not need AC, which is still quite dangerous, tho I am not sure about the scale of future version, as well as we would need pump body for it, though in this case maybe in automotive we can find something? AFAIR for example BMW used pump from Polyphenyl Sulfphide, thus maybe we could go this way?

-

We need something robust and capable of continuous duty, do stepper motors that? We don't need very precise speed control.

I don't think we need closed-loop control. We want to vary the speed so that when the battery is charging/discharging at low/intermediate power levels, we can decrease the pumping losses because the rate of forced convection (pumping) doesn't need to be very high. Also, being able to ramp up/down the flow decreases mechanical stresses on bipolar plates in the stack (fatigue from pump cycle on/off). When the battery is charge/discharging at max power, the pumps are on max. It doesn't matter precisely what the flow rate is, controlling the effective speed in an open-loop way should be enough I think. You can detect changes in pump speed in the current/voltage data of the battery, and if we are monitoring AC power to the pumps as well as DC power in/out of battery, a control system should be able to minimize the objective function that is [AC power to pumps - abs(DC power in/out of battery)], without needing to know the exact flowrate/pressure.

-

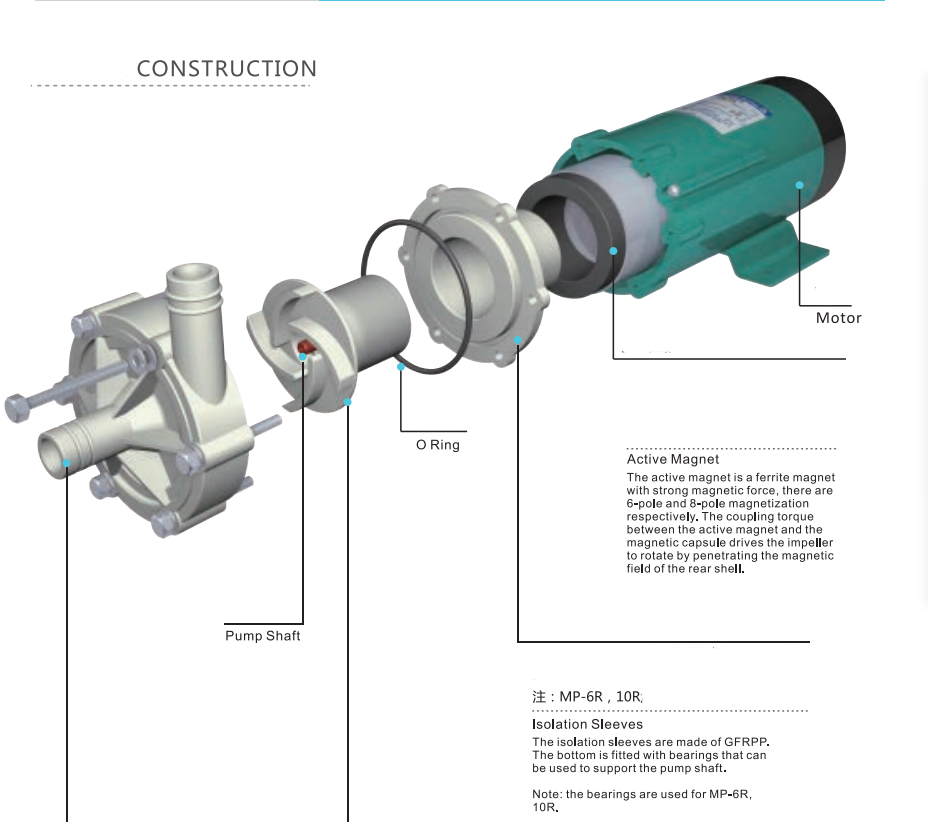

We do need centrifugal pumps that are magnetically driven, with no rotating seals - that's a must.

This is only a test rig, but relevant: https://www.hardware-x.com/article/S2468-0672(20)30049-3/fulltext (and they used a stepper motor to drive the pump)

-

There are also options along the lines of these pumps:

http://lg-motor.com/en/Products/list_460.html

https://www.topsflo.com/brushless-dc-centrifugal-pumps/

But I don't know their wetted components.

I will talk to the original manufacturer of the green pump about brushless DC options.

-

-

@slash909uk@mastodon.me.uk thanks for the response, yes flow needs to be constant unfortunately. I can use these pumps at full speed no problem, but for various reasons - efficiency, managing pressure differentials in the stack - it would be nice to control their speed. The manufacturer may have another option for that, in the meantime we can make progress without speed control. The motor could also be swapped out keeping the pump head, but that might be tricky.

@kirk ah ok, good luck!

-

Okay, I have not fully understood this idea yet

So as of now it seems that NEMAs' are overkill due to higher costs, as we do not need precise steering (I thought that it would be nice).

In this case if we agree with the lower power of BLDC imho it seems to be a good way to go - they are pretty cheap, there are few already integrated in valid pumps, and we remain on low voltage DC, which is safer.

We need something robust and capable of continuous duty,

Steppers should be okay with that, they might lose some steps, but in our case it should not be a problem at all. Of course for prototyping, in general you are right BLDC will be way better (mostly due to costs), and in final, big version 3 phase, inverter driven engines will be probably the best. Nevertheless I think the medium prototype should use safe voltage, so everybody can transport and work on it without risk

Also in case of knowing exact RPMs - closed loop based on objective function [

ACDC power to pumps - abs(DC power in/out of battery)] with BLDC can be used as well? Moreover RPM knowledge gives a opportunity to detect for example stall of the pump, or other pump-related issues faster? Idk what will happen to the battery if one of pumps fails. -

Okay, I have not fully understood this idea yet

So as of now it seems that NEMAs' are overkill due to higher costs, as we do not need precise steering (I thought that it would be nice).

In this case if we agree with the lower power of BLDC imho it seems to be a good way to go - they are pretty cheap, there are few already integrated in valid pumps, and we remain on low voltage DC, which is safer.

We need something robust and capable of continuous duty,

Steppers should be okay with that, they might lose some steps, but in our case it should not be a problem at all. Of course for prototyping, in general you are right BLDC will be way better (mostly due to costs), and in final, big version 3 phase, inverter driven engines will be probably the best. Nevertheless I think the medium prototype should use safe voltage, so everybody can transport and work on it without risk

Also in case of knowing exact RPMs - closed loop based on objective function [

ACDC power to pumps - abs(DC power in/out of battery)] with BLDC can be used as well? Moreover RPM knowledge gives a opportunity to detect for example stall of the pump, or other pump-related issues faster? Idk what will happen to the battery if one of pumps fails.@H4K1 said in How should we control the centrifugal pumps? TRIAC/thyristor etc? Need help from controls/electrical people:

So as of now it seems that NEMAs' are overkill due to higher costs, as we do not need precise steering (I thought that it would be nice).

Precise speed control isn't necessary, mostly just knowing that "the pumps are running at 50% of max power" for example.

In this case if we agree with the lower power of BLDC imho it seems to be a good way to go - they are pretty cheap, there are few already integrated in valid pumps, and we remain on low voltage DC, which is safer.

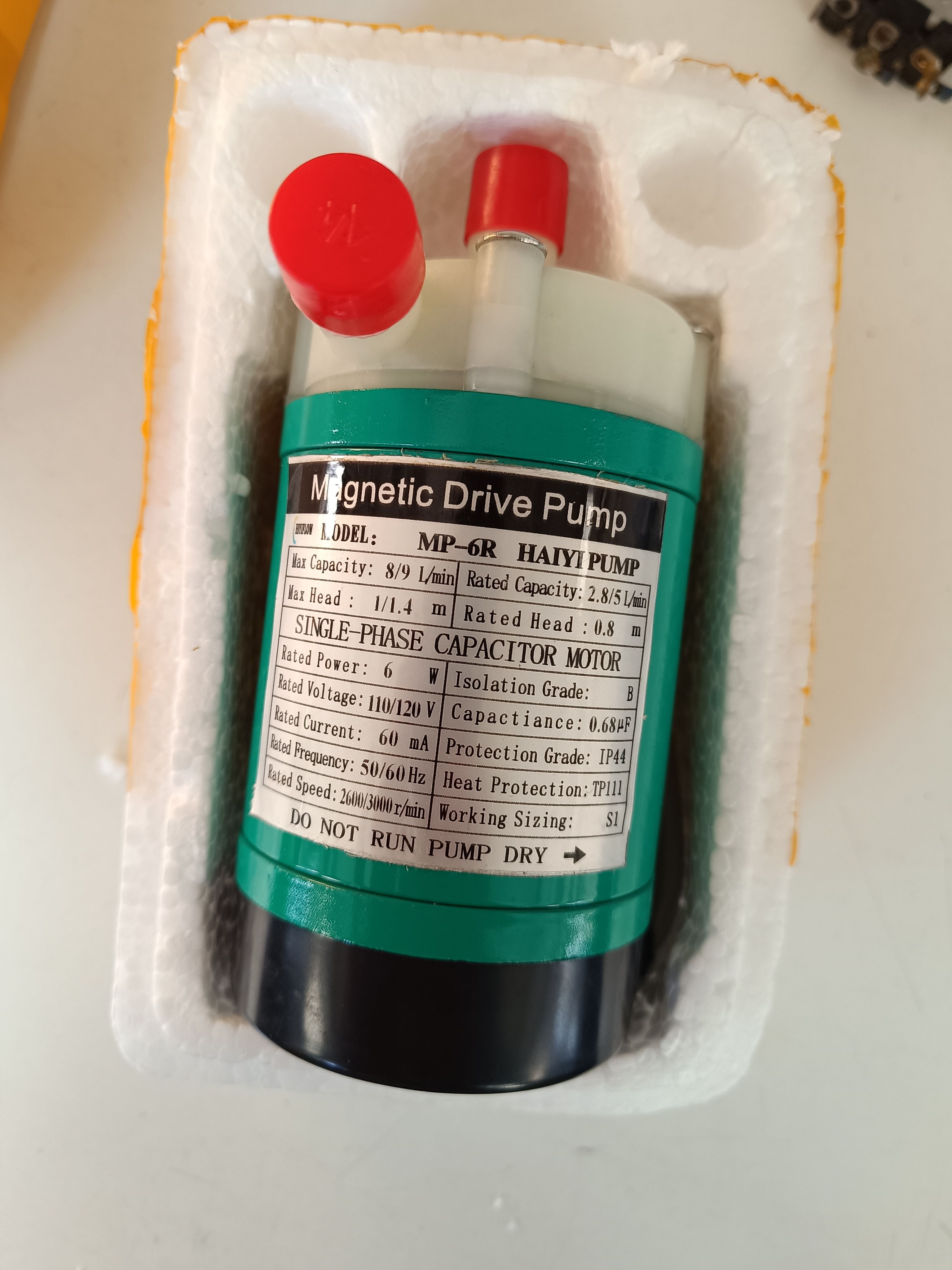

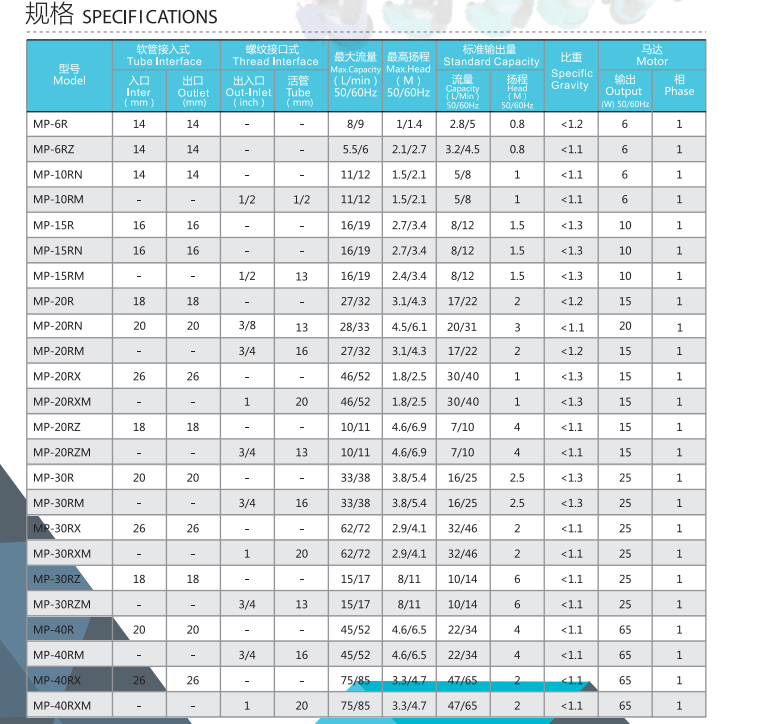

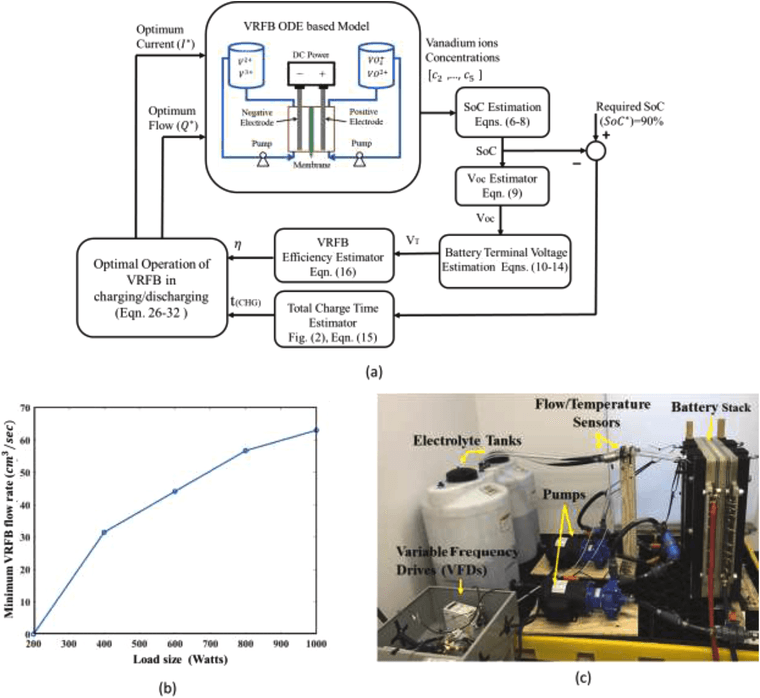

I'm not sure those BLDC pumps from Topsflo and LG Motor I linked to would be chemically compatible. The green Haiyi MP-6R pumps are designed for continuous use with chemicals (they're mostly polypropylene), so I wanted to start with them first since I'd bet on them being more robust.

We need something robust and capable of continuous duty,

Steppers should be okay with that, they might lose some steps, but in our case it should not be a problem at all. Of course for prototyping, in general you are right BLDC will be way better (mostly due to costs), and in final, big version 3 phase, inverter driven engines will be probably the best. Nevertheless I think the medium prototype should use safe voltage, so everybody can transport and work on it without risk

Totally agree on the safe voltage aspect! It doesn't matter much what the pumps run on, it only matters how it affects cost/safety/complexity/durability.

Also in case of knowing exact RPMs - closed loop based on objective function [

ACDC power to pumps - abs(DC power in/out of battery)] with BLDC can be used as well? Moreover RPM knowledge gives a opportunity to detect for example stall of the pump, or other pump-related issues faster? Idk what will happen to the battery if one of pumps fails.So this loop I mentioned doesn't have to be implemented right away. In a real RFB you try to minimize energy losses from pumping. Pumping faster increases the rate at which you can charge/discharge, and/or improves the efficiency of your battery, but only to a certain threshold. There is then a local optimum pump flowrate, for a given applied current to the battery, that will lead to the best electrochemical performance with the lowest pumping energy. In a real-world application, this would need to be adjusted in real-time to have the best performance. For testing, it doesn't matter as much. Whether the pump motors are AC or DC doesn't matter, just their total power consumption.

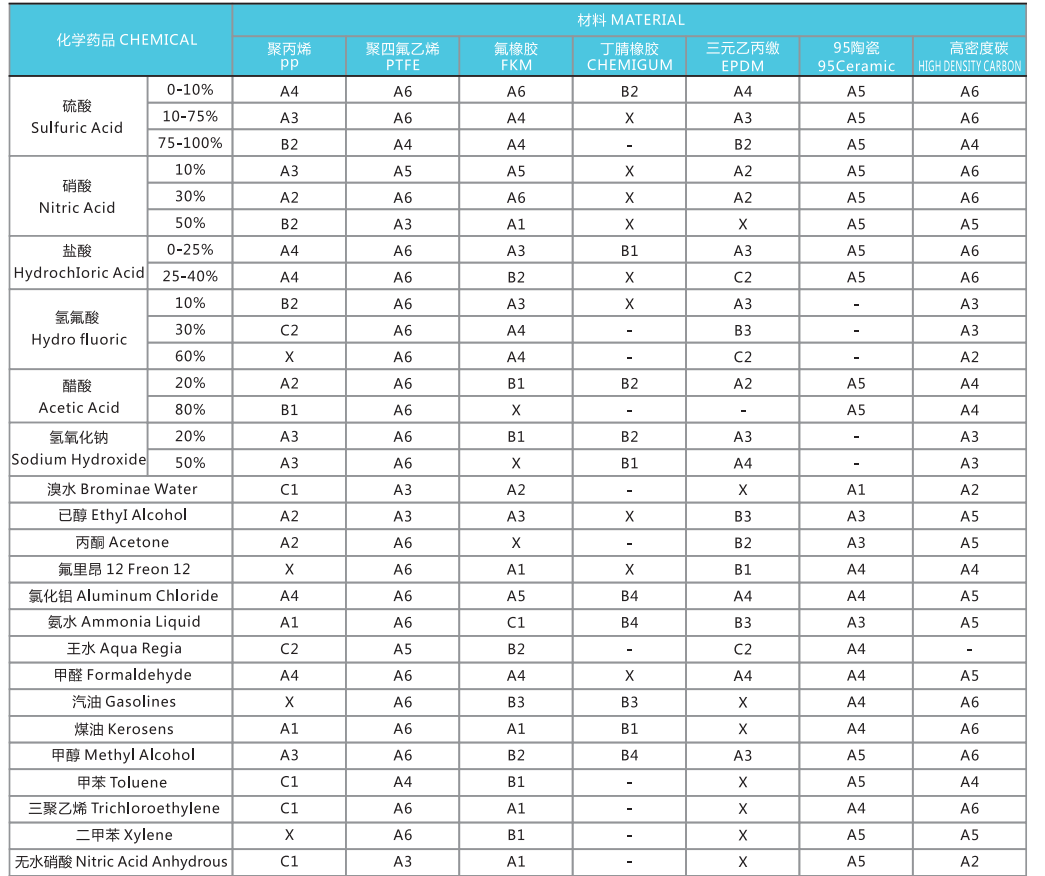

This is a figure from a paper, ignore the different electrode types (that's what they were studying):

You want to be in the regime of

- high current density, low pressure drop (lower right in subfigure a).

- high electric power, low pumping power (lower right in subfigure b).

(btw, we are using felts, the orange triangles in these curves - they are cheap and simple to use, this paper is exploring alternatives).

Also, detecting pump failure/stalling is probably a good idea. A failed pump will lead to a rapid increase/decrease in voltage, since the electrolyte will no longer be delivered to one half of the stack. Could detect a few different ways, just thinking here:

- flow switch/meter in the flow loop

- pump rpm measurement

- detecting it from current/voltage data in the DC charge/discharge behavior

-

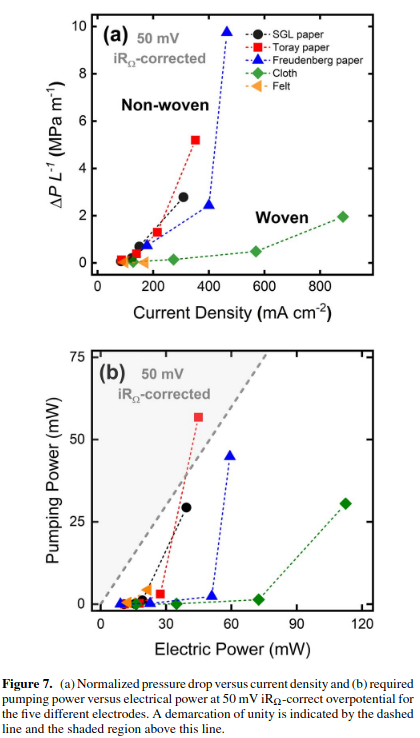

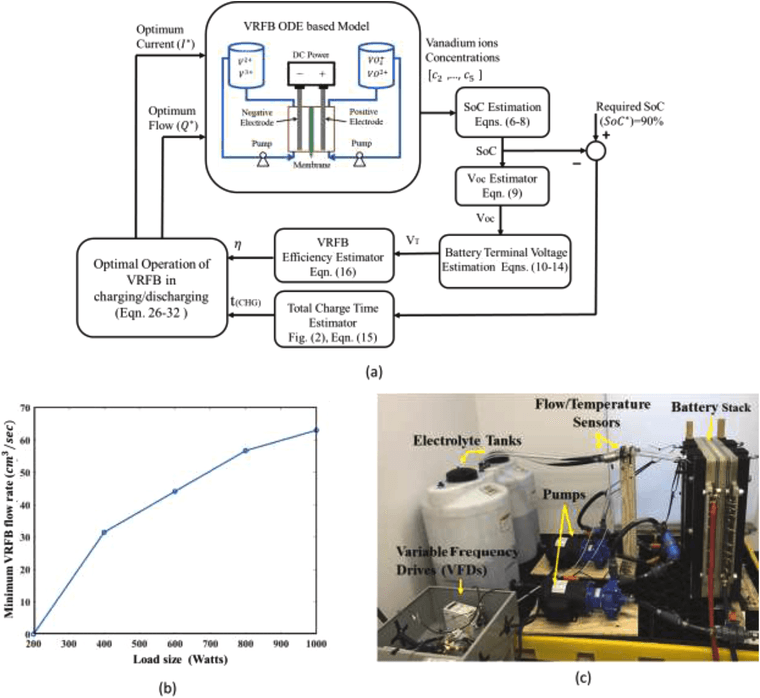

@H4K1 this is more what I was talking about! Found a relevant paper: https://www.sciencedirect.com/science/article/pii/S0378775321007229

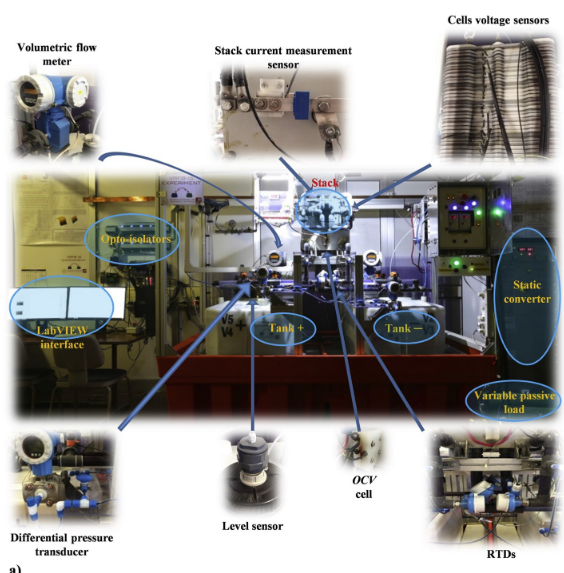

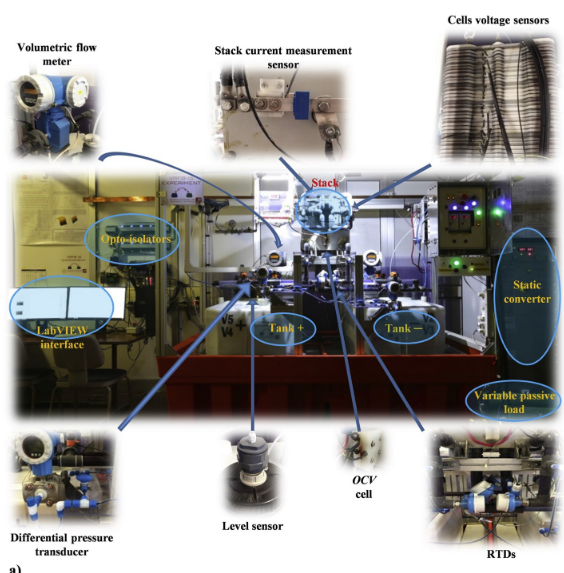

Here is paper based on the very helpful thesis of Andrea Trovò:

We probably can't afford all these sensors... but they are more useful for pure academic work. We are just trying to get to a minimum viable system! We don't need full-on characterization of every value.

-

Very relevant work by Trovò: https://www.sciencedirect.com/science/article/abs/pii/S0306261920300441

Seems they basically used a lookup table based on flowrate and SOC.

-

K kirk referenced this topic on

K kirk referenced this topic on

-

@H4K1 this is more what I was talking about! Found a relevant paper: https://www.sciencedirect.com/science/article/pii/S0378775321007229

Here is paper based on the very helpful thesis of Andrea Trovò:

We probably can't afford all these sensors... but they are more useful for pure academic work. We are just trying to get to a minimum viable system! We don't need full-on characterization of every value.

Having the extra sensors makes more sense from the perspective of prototyping/experimenting.

Once the design moves towards the stable-release version, the number could be reduced, so the measurements are mostly the metrics needed to troubleshoot operations and ensure safety.

I've seen this approach used in the catering industry, for larger-scale manufacturing of sweets and pastries.

The intial prototypes had way more sensors than the versions that were installed on the factory floor.

Also, the food-safe pump designs will be worth looking at. As they are designed to conform with the food-hygiene standards, they'll operate to a known standard of predictability in their behaviour, so it will reduce the random factors involved when experimenting with designs.

As they are simple discrete modules, even in the larger assembly-lines, they'll fit nicely in the user-process-flow when things start to move towards the design-for-manufacturability stage.

-

I agree about loading up on sensors and then cutting them to the bare minimum as things mature---though some process sensors for chemicals can be pricey!

Are those food-safe pumps centrifugal? We need those to be power efficient---peristaltic won't do at scale.Edit: saw your other comment, if these mag-drive centrifugal pumps are common in that industry that's great! Do you know what materials are commonly used and come into liquid contact? And what range of flowrates they can provide?

-

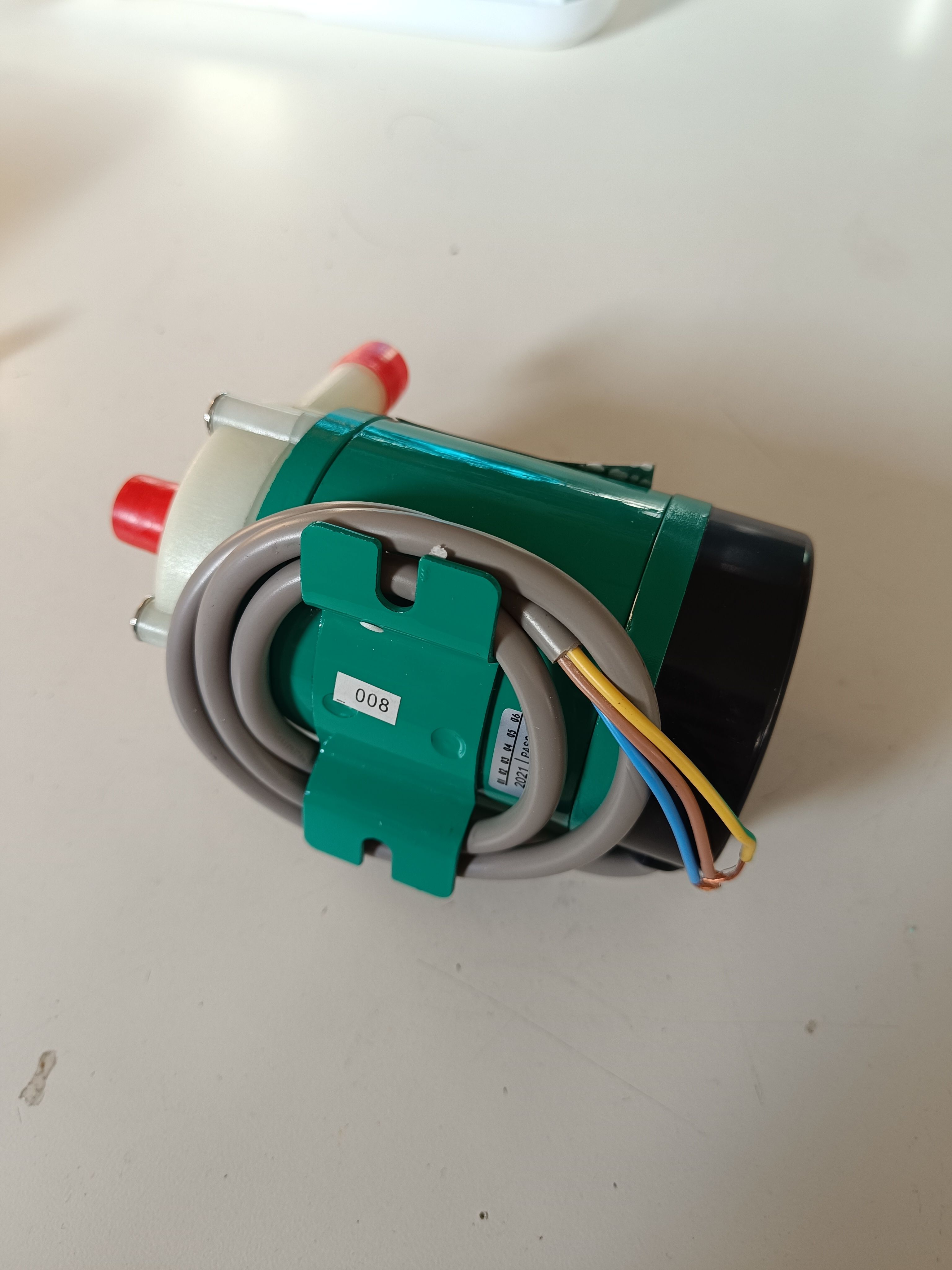

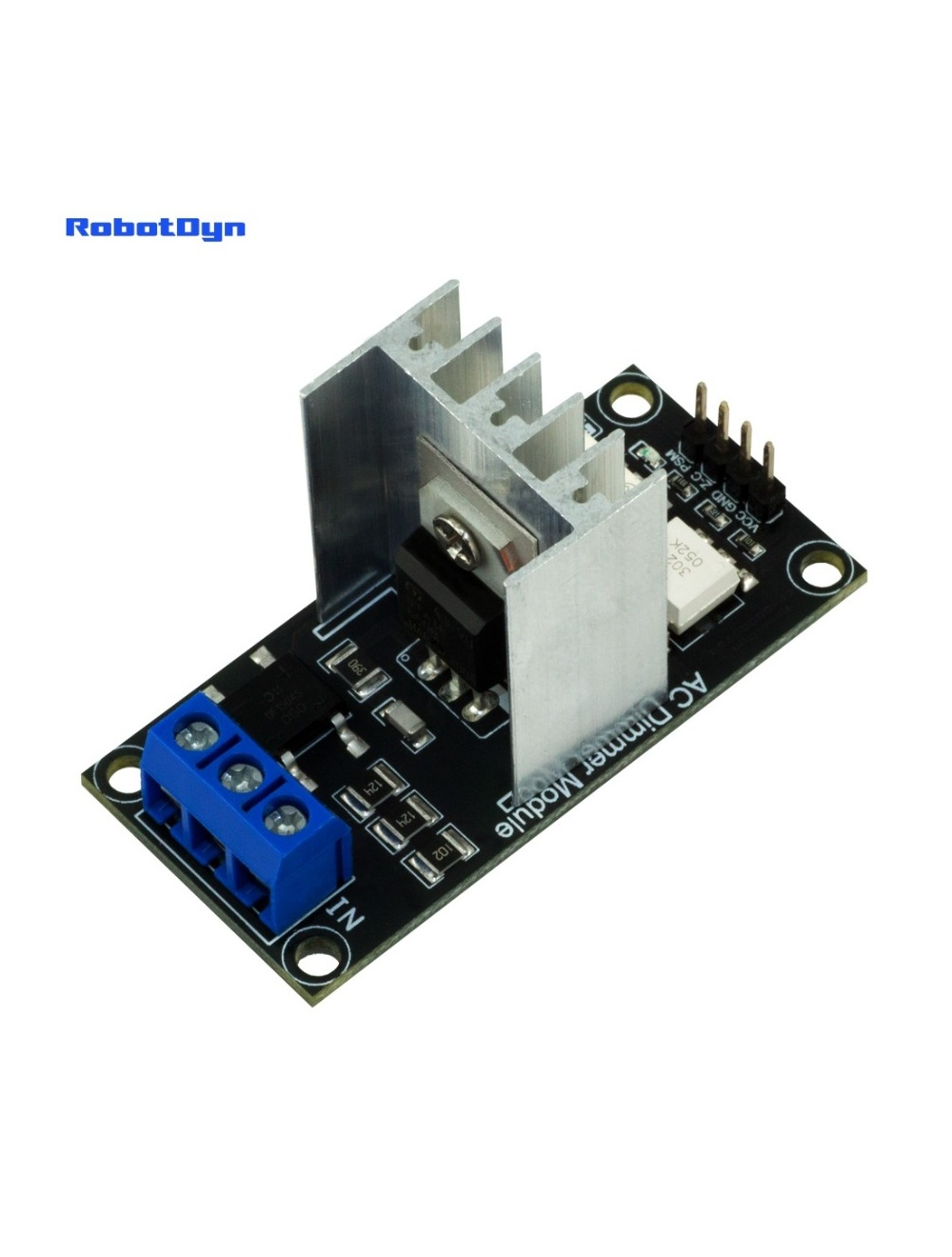

Tested the pumps today, they work just fine switched on 110 V AC, will try the triac, if that doesn't work/it fries the motor, will disassemble and try to get a different motor on there.

Video of pumps running: https://spectra.video/w/9VddoPTvMvDCJ121B4fabf

-

@methylzero@mast.hpc.social @BillySmith @H4K1 @slash909uk@mastodon.me.uk

It seems to work! At least enough for testing purposes. Here is a video: https://spectra.video/w/8xipM8aXnBkDXnu4kkRpqT

-

@methylzero@mast.hpc.social @BillySmith @H4K1 @slash909uk@mastodon.me.uk

It seems to work! At least enough for testing purposes. Here is a video: https://spectra.video/w/8xipM8aXnBkDXnu4kkRpqT

@kirk @Slash909uk Nice! Better than I expected honestly. At the low end of the speed range it sounds a bit unhappy. The thermal protection is only TP111 so it may not be fast enough to save the motor if it is stalled.

If this motor does work out, the manufacturer can make bigger ones and apparently you can choose the wet-side material. http://www.china-haiyi.com/product-48054-173640.html -

@kirk @Slash909uk Nice! Better than I expected honestly. At the low end of the speed range it sounds a bit unhappy. The thermal protection is only TP111 so it may not be fast enough to save the motor if it is stalled.

If this motor does work out, the manufacturer can make bigger ones and apparently you can choose the wet-side material. http://www.china-haiyi.com/product-48054-173640.html@kirk @Slash909uk But one thing not good about these pumps is that they might not work great with really dense solutions, max. density is 1.1-1.3 depending on the model, which is .... not much.

-

@kirk @Slash909uk Nice! Better than I expected honestly. At the low end of the speed range it sounds a bit unhappy. The thermal protection is only TP111 so it may not be fast enough to save the motor if it is stalled.

If this motor does work out, the manufacturer can make bigger ones and apparently you can choose the wet-side material. http://www.china-haiyi.com/product-48054-173640.html@methylzero@mast.hpc.social said in How should we control the centrifugal pumps? TRIAC/thyristor etc? Need help from controls/electrical people:

Nice! Better than I expected honestly. At the low end of the speed range it sounds a bit unhappy. The thermal protection is only TP111 so it may not be fast enough to save the motor if it is stalled.

If this motor does work out, the manufacturer can make bigger ones and apparently you can choose the wet-side material. http://www.china-haiyi.com/product-48054-173640.htmlThank! I read some stuff that TRIACs can work for very small motors, and indeed this is only around 6 W, so I figured why not just try it. Yes, at the low end it made some funny sounds, nothing horrible, but this is not definitely not the optimal control strategy. It should hopefully allow us to do single-cell flow testing at close-to-appropriate flowrates, without having crazy fast flow or having to add a bunch of (chemically resistant) plumbing like a bypass/pump-around. For wet-side I think they have two standard options of PP and PVDF for the housing/impeller. Also, for some bigger pumps, they offer BLDC motors stock, apparently, which should be easier to slow down efficiently. Didn't know that TP111 designation either - sounds like it should auto-shut off if it gets too hot at steady state, but won't protect from a stall.

Also, just FYI, R.Flo, a Ukrainian all-iron RFB startup, posted a pic on LinkedIn with these pumps:

Which look to be the same version, but larger.

@methylzero@mast.hpc.social said in How should we control the centrifugal pumps? TRIAC/thyristor etc? Need help from controls/electrical people:

But one thing not good about these pumps is that they might not work great with really dense solutions, max. density is 1.1-1.3 depending on the model, which is .... not much.

Yeah I saw this and... we will cross that bridge if/when we get to it

at this low of a price point I read the datasheets with a shaker of salt.

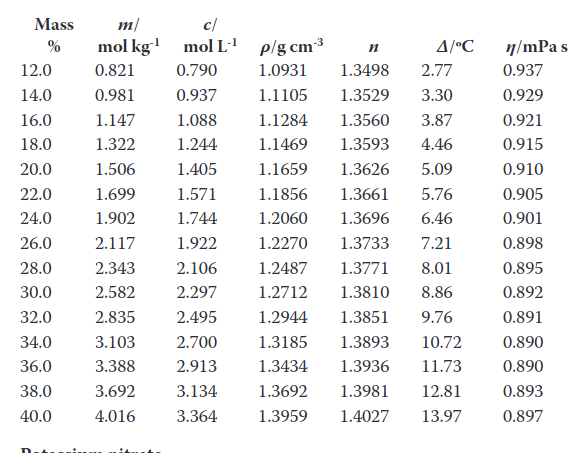

at this low of a price point I read the datasheets with a shaker of salt.From CRC handbook for potassium iodide (just as a reference point for a salt we currently test with):

In real electrolytes we'll have other salts present at the same time, but even with a 1.3 SG max we may get to reasonable concentrations---as in, high enough to allow us to build out the rest of the system for a prototype. I figure over 1.3 SG the pump either fails faster or has otherwise reduced performance, but maybe we'll find out the hard way

-

@methylzero@mast.hpc.social @BillySmith @H4K1 @slash909uk@mastodon.me.uk

It seems to work! At least enough for testing purposes. Here is a video: https://spectra.video/w/8xipM8aXnBkDXnu4kkRpqT

@kirk said in How should we control the centrifugal pumps? TRIAC/thyristor etc? Need help from controls/electrical people:

It seems to work! At least enough for testing purposes. Here is a video: https://spectra.video/w/8xipM8aXnBkDXnu4kkRpqT

Here is the code for this test: https://codeberg.org/FBRC/RFB-test-cell/src/commit/d10834bc7dd67736e708c9a33832a5602ab3ca28/firmware/FlowrateRampTest.ino

-

K kirk referenced this topic on

K kirk referenced this topic on