How should we control the centrifugal pumps? TRIAC/thyristor etc? Need help from controls/electrical people

-

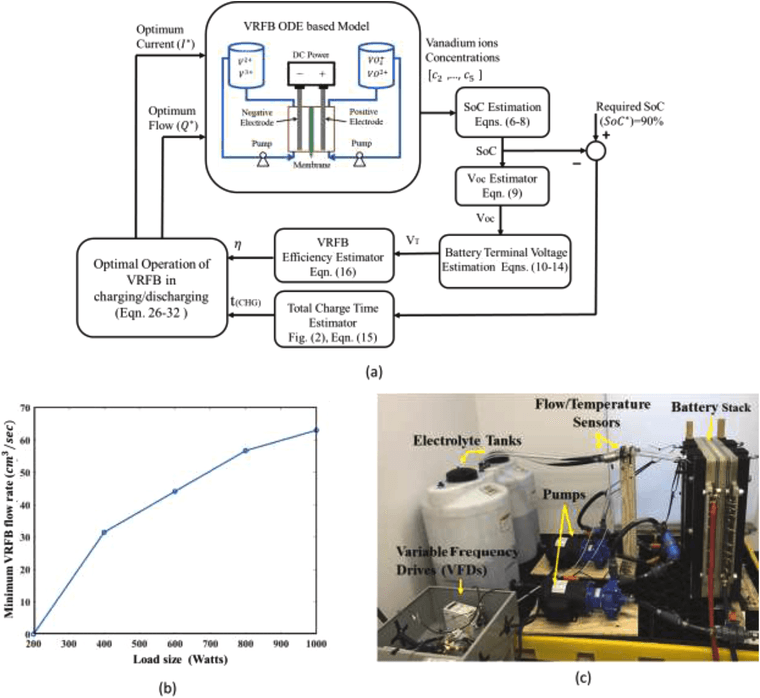

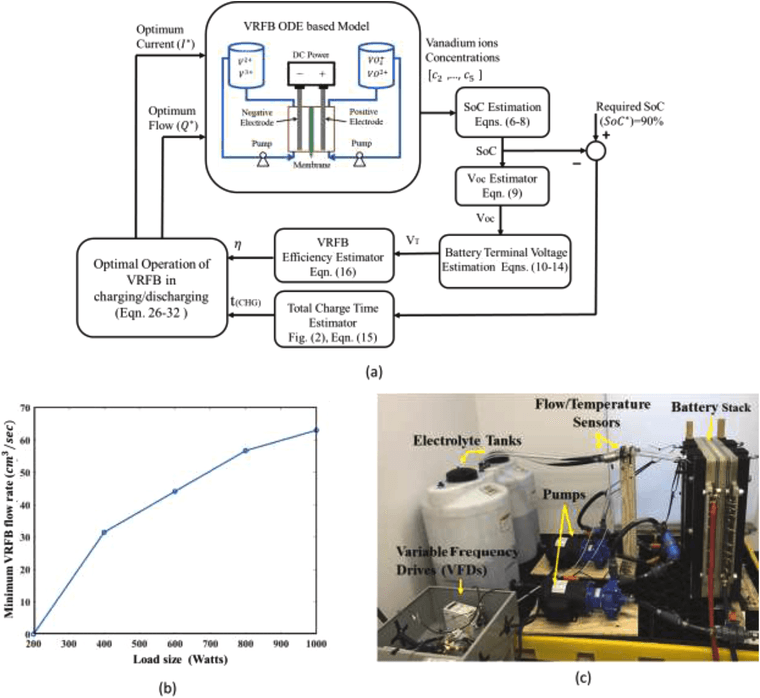

@H4K1 this is more what I was talking about! Found a relevant paper: https://www.sciencedirect.com/science/article/pii/S0378775321007229

Here is paper based on the very helpful thesis of Andrea Trovò:

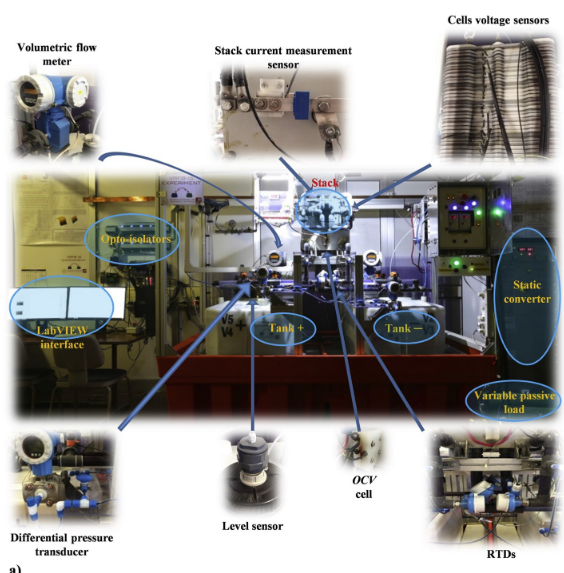

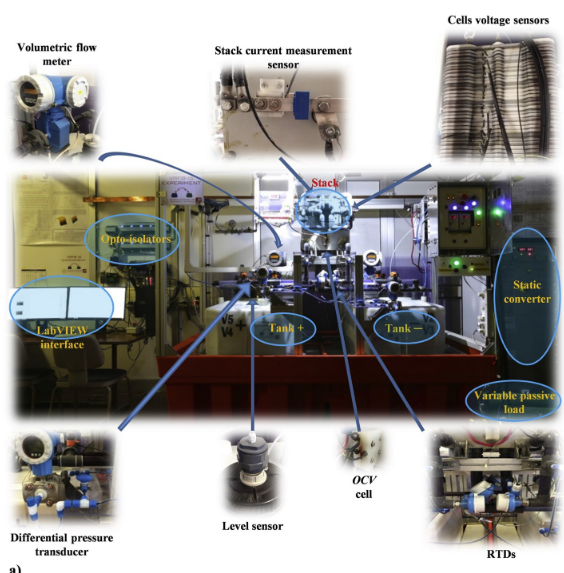

We probably can't afford all these sensors... but they are more useful for pure academic work. We are just trying to get to a minimum viable system! We don't need full-on characterization of every value.

-

Very relevant work by Trovò: https://www.sciencedirect.com/science/article/abs/pii/S0306261920300441

Seems they basically used a lookup table based on flowrate and SOC.

-

K kirk referenced this topic on

K kirk referenced this topic on

-

@H4K1 this is more what I was talking about! Found a relevant paper: https://www.sciencedirect.com/science/article/pii/S0378775321007229

Here is paper based on the very helpful thesis of Andrea Trovò:

We probably can't afford all these sensors... but they are more useful for pure academic work. We are just trying to get to a minimum viable system! We don't need full-on characterization of every value.

Having the extra sensors makes more sense from the perspective of prototyping/experimenting.

Once the design moves towards the stable-release version, the number could be reduced, so the measurements are mostly the metrics needed to troubleshoot operations and ensure safety.

I've seen this approach used in the catering industry, for larger-scale manufacturing of sweets and pastries.

The intial prototypes had way more sensors than the versions that were installed on the factory floor.

Also, the food-safe pump designs will be worth looking at. As they are designed to conform with the food-hygiene standards, they'll operate to a known standard of predictability in their behaviour, so it will reduce the random factors involved when experimenting with designs.

As they are simple discrete modules, even in the larger assembly-lines, they'll fit nicely in the user-process-flow when things start to move towards the design-for-manufacturability stage.

-

I agree about loading up on sensors and then cutting them to the bare minimum as things mature---though some process sensors for chemicals can be pricey!

Are those food-safe pumps centrifugal? We need those to be power efficient---peristaltic won't do at scale.Edit: saw your other comment, if these mag-drive centrifugal pumps are common in that industry that's great! Do you know what materials are commonly used and come into liquid contact? And what range of flowrates they can provide?

-

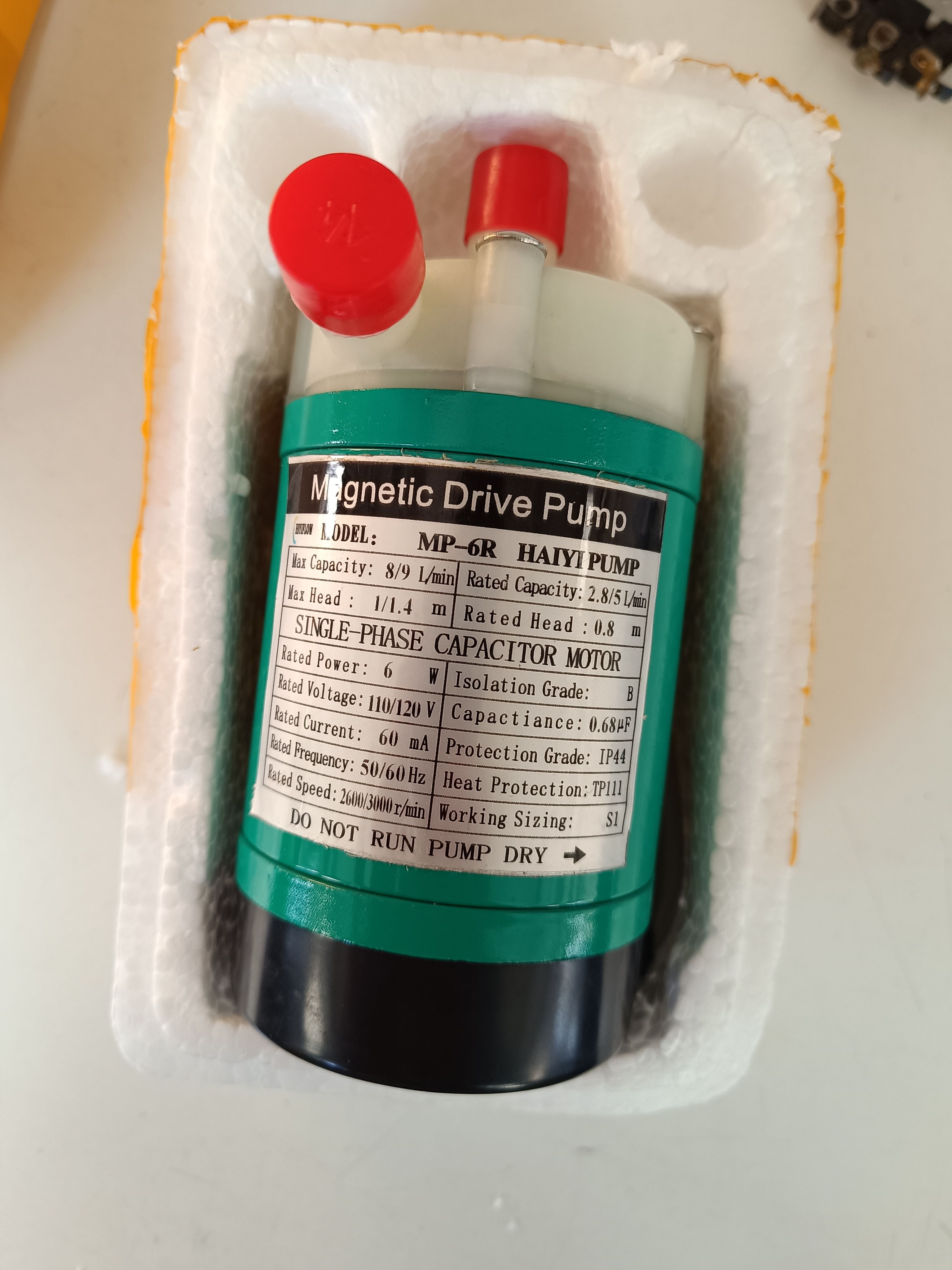

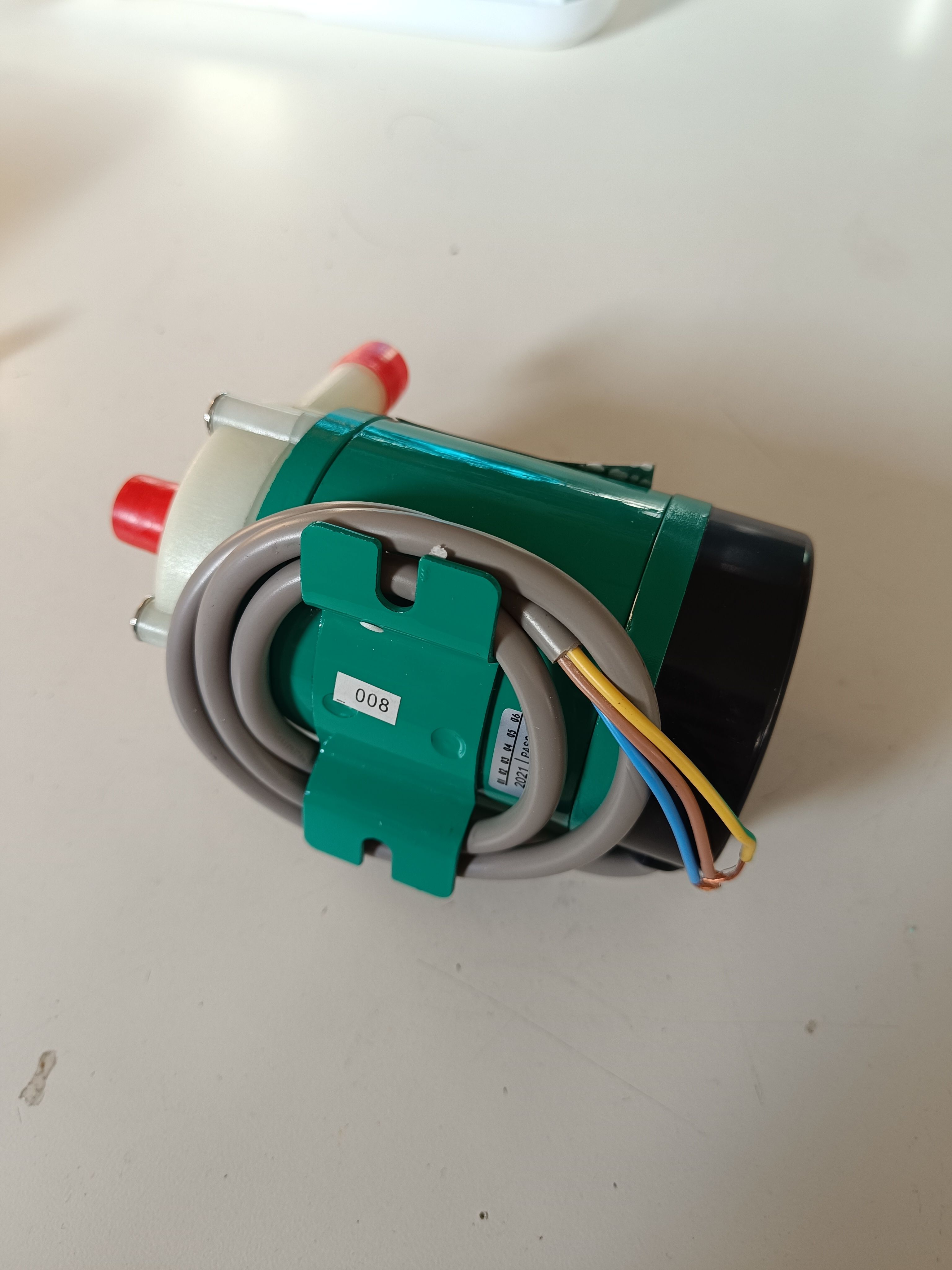

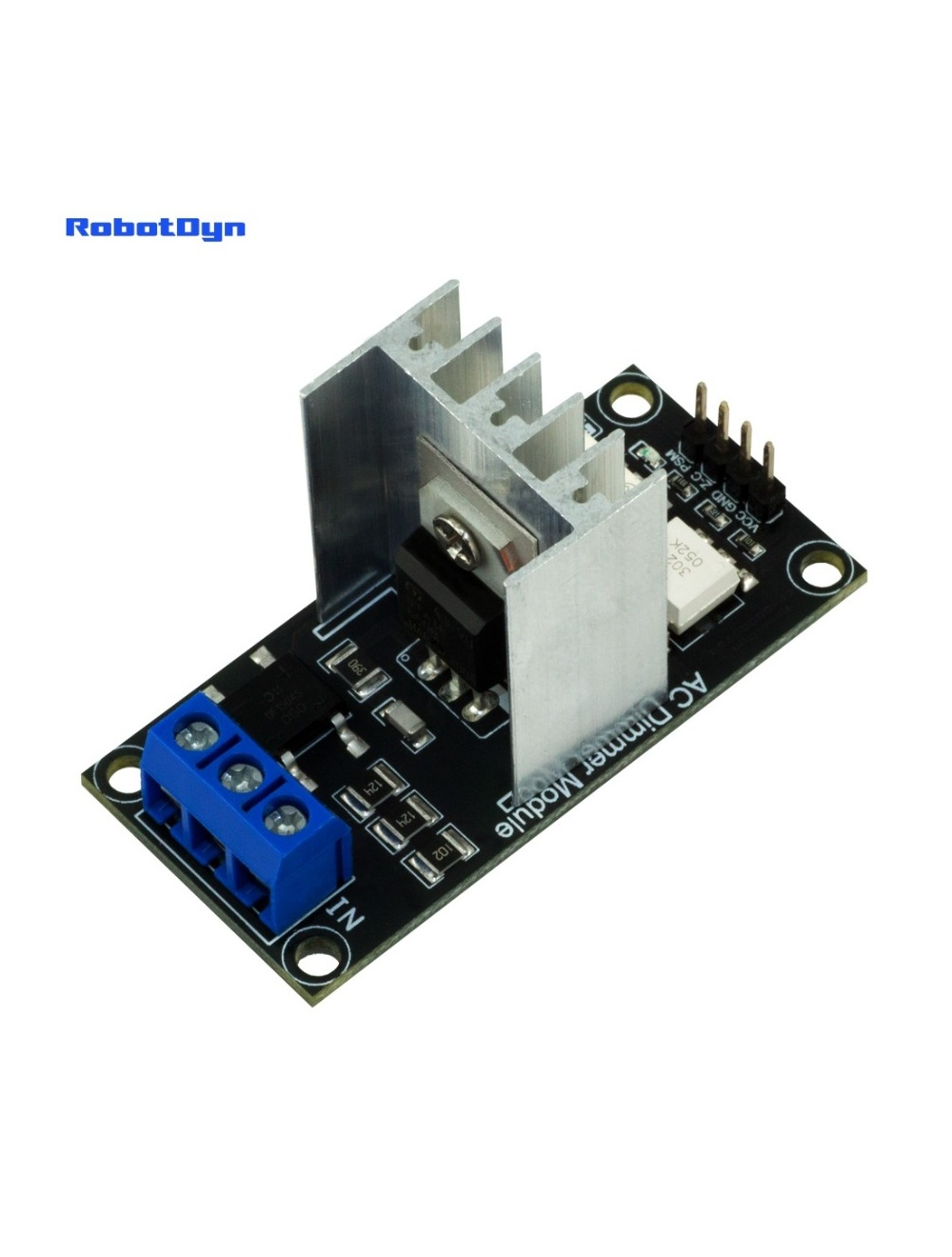

Tested the pumps today, they work just fine switched on 110 V AC, will try the triac, if that doesn't work/it fries the motor, will disassemble and try to get a different motor on there.

Video of pumps running: https://spectra.video/w/9VddoPTvMvDCJ121B4fabf

-

@methylzero@mast.hpc.social @BillySmith @H4K1 @slash909uk@mastodon.me.uk

It seems to work! At least enough for testing purposes. Here is a video: https://spectra.video/w/8xipM8aXnBkDXnu4kkRpqT

-

@methylzero@mast.hpc.social @BillySmith @H4K1 @slash909uk@mastodon.me.uk

It seems to work! At least enough for testing purposes. Here is a video: https://spectra.video/w/8xipM8aXnBkDXnu4kkRpqT

@kirk @Slash909uk Nice! Better than I expected honestly. At the low end of the speed range it sounds a bit unhappy. The thermal protection is only TP111 so it may not be fast enough to save the motor if it is stalled.

If this motor does work out, the manufacturer can make bigger ones and apparently you can choose the wet-side material. http://www.china-haiyi.com/product-48054-173640.html -

@kirk @Slash909uk Nice! Better than I expected honestly. At the low end of the speed range it sounds a bit unhappy. The thermal protection is only TP111 so it may not be fast enough to save the motor if it is stalled.

If this motor does work out, the manufacturer can make bigger ones and apparently you can choose the wet-side material. http://www.china-haiyi.com/product-48054-173640.html@kirk @Slash909uk But one thing not good about these pumps is that they might not work great with really dense solutions, max. density is 1.1-1.3 depending on the model, which is .... not much.

-

@kirk @Slash909uk Nice! Better than I expected honestly. At the low end of the speed range it sounds a bit unhappy. The thermal protection is only TP111 so it may not be fast enough to save the motor if it is stalled.

If this motor does work out, the manufacturer can make bigger ones and apparently you can choose the wet-side material. http://www.china-haiyi.com/product-48054-173640.html@methylzero@mast.hpc.social said in How should we control the centrifugal pumps? TRIAC/thyristor etc? Need help from controls/electrical people:

Nice! Better than I expected honestly. At the low end of the speed range it sounds a bit unhappy. The thermal protection is only TP111 so it may not be fast enough to save the motor if it is stalled.

If this motor does work out, the manufacturer can make bigger ones and apparently you can choose the wet-side material. http://www.china-haiyi.com/product-48054-173640.htmlThank! I read some stuff that TRIACs can work for very small motors, and indeed this is only around 6 W, so I figured why not just try it. Yes, at the low end it made some funny sounds, nothing horrible, but this is not definitely not the optimal control strategy. It should hopefully allow us to do single-cell flow testing at close-to-appropriate flowrates, without having crazy fast flow or having to add a bunch of (chemically resistant) plumbing like a bypass/pump-around. For wet-side I think they have two standard options of PP and PVDF for the housing/impeller. Also, for some bigger pumps, they offer BLDC motors stock, apparently, which should be easier to slow down efficiently. Didn't know that TP111 designation either - sounds like it should auto-shut off if it gets too hot at steady state, but won't protect from a stall.

Also, just FYI, R.Flo, a Ukrainian all-iron RFB startup, posted a pic on LinkedIn with these pumps:

Which look to be the same version, but larger.

@methylzero@mast.hpc.social said in How should we control the centrifugal pumps? TRIAC/thyristor etc? Need help from controls/electrical people:

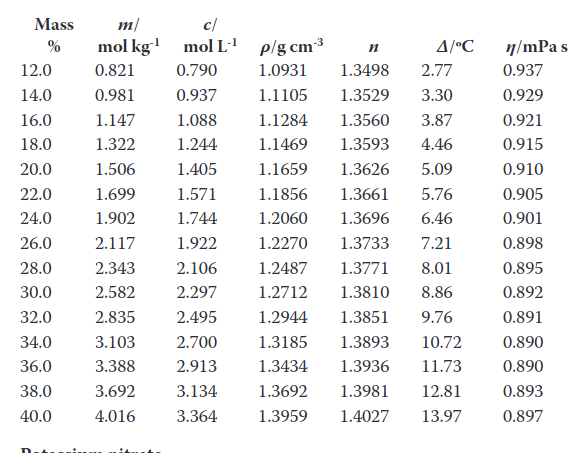

But one thing not good about these pumps is that they might not work great with really dense solutions, max. density is 1.1-1.3 depending on the model, which is .... not much.

Yeah I saw this and... we will cross that bridge if/when we get to it

at this low of a price point I read the datasheets with a shaker of salt.

at this low of a price point I read the datasheets with a shaker of salt.From CRC handbook for potassium iodide (just as a reference point for a salt we currently test with):

In real electrolytes we'll have other salts present at the same time, but even with a 1.3 SG max we may get to reasonable concentrations---as in, high enough to allow us to build out the rest of the system for a prototype. I figure over 1.3 SG the pump either fails faster or has otherwise reduced performance, but maybe we'll find out the hard way

-

@methylzero@mast.hpc.social @BillySmith @H4K1 @slash909uk@mastodon.me.uk

It seems to work! At least enough for testing purposes. Here is a video: https://spectra.video/w/8xipM8aXnBkDXnu4kkRpqT

@kirk said in How should we control the centrifugal pumps? TRIAC/thyristor etc? Need help from controls/electrical people:

It seems to work! At least enough for testing purposes. Here is a video: https://spectra.video/w/8xipM8aXnBkDXnu4kkRpqT

Here is the code for this test: https://codeberg.org/FBRC/RFB-test-cell/src/commit/d10834bc7dd67736e708c9a33832a5602ab3ca28/firmware/FlowrateRampTest.ino

-

K kirk referenced this topic on

K kirk referenced this topic on