Thanks Kirk!

Here's a brief update. I've decided to see how I can make this with the simplest of tools (i.e., thinking if one didn't have access to CNC or a manual mill).

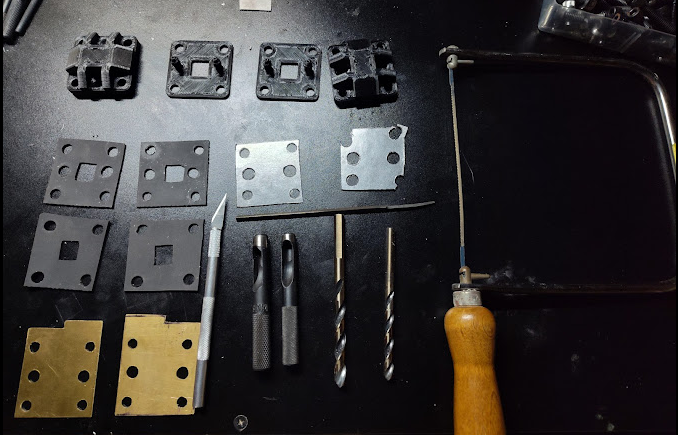

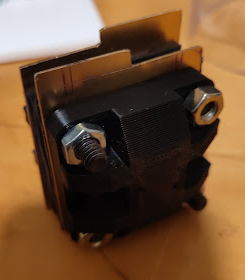

I've found that using hand files, drill bits, and a coping saw (24 tpi bimetal blade), I can make the current collectors of 1 mm brass with a little elbow grease (WD-40 made the cutting substantially easier). My hacksaw was not a great choice for the thin brass.

In addition, by printing the gasket template for a guide, and then cutting the holes and cavity with some cheap circular punches and an x-acto knife, I got some jenky gaskets.

Not the prettiest, but I'll refine my technique as needed. I'm eager to get to leak testing to see whether my printing settings are OK.

Also, should I have made this a blog post? Happy to delete and move if that's better.

.

.