Blog: czahl's build

-

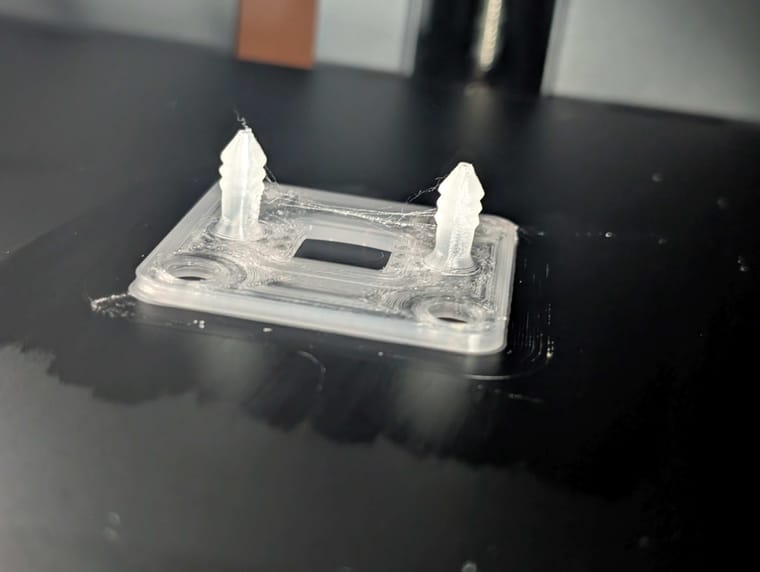

Yesterday I made a new test with the BASF Ultrafuse PP filament - and it behaves totally different. When keeping all the parameters as before, it was loosen from the tape after some layers. I also noticed massive warping, the brims were also warped up.

Next I used the print profile from BASF. It uses a much higher temperature (which is not in line with the datasheet), but the result was the same. In addition, the packing tape melted so I had to remove it.

Next I used a this film of MAGIGOO PP adhesive glue, which gives a good result:

It has some stringing (might be because of the high temp) but fastened to the printing plate quiet well. Removal after cooling down was also easy. Unfortunately, the flow was too much so that the hole in the port was solid. I need to tune the parameters further or to use the new update from @kirk where the inner diameter is increased from 2 to 3mm.@czahl said in Blog: czahl's build:

the new update from @kirk where the inner diameter is increased from 2 to 3mm.

Also good catch, @danielfp248 has tested this already and it results in smoother flow/less pressure drop in the system without introducing new leakage it appears.

-

@czahl said in Blog: czahl's build:

the new update from @kirk where the inner diameter is increased from 2 to 3mm.

Also good catch, @danielfp248 has tested this already and it results in smoother flow/less pressure drop in the system without introducing new leakage it appears.

-

@sepi It was necessary when I had a much worse printer, lol. But I think any decent printer should be able to handle the wall thickness when the holes are 3mm on both the reservoirs and the flow frames.

-

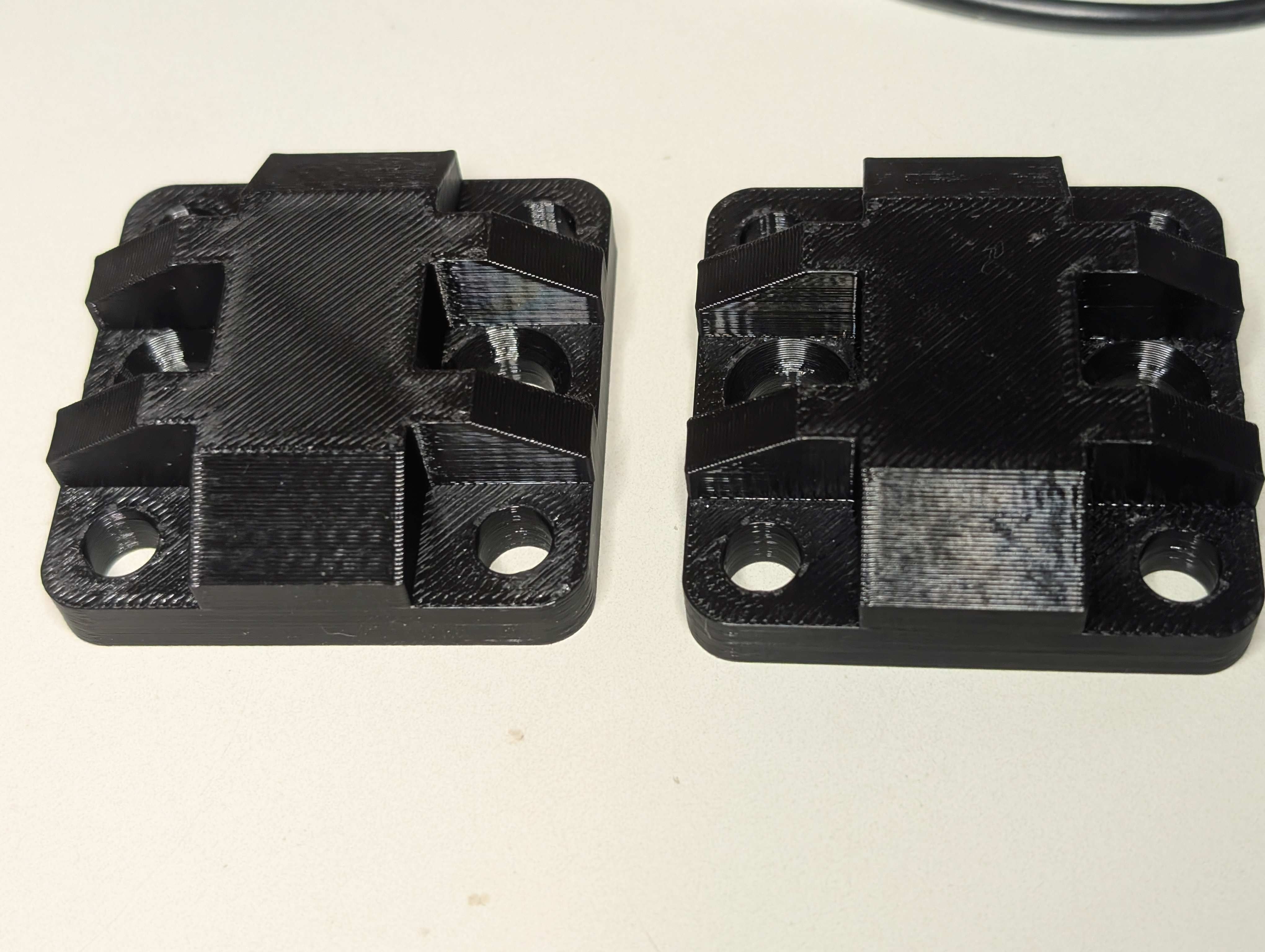

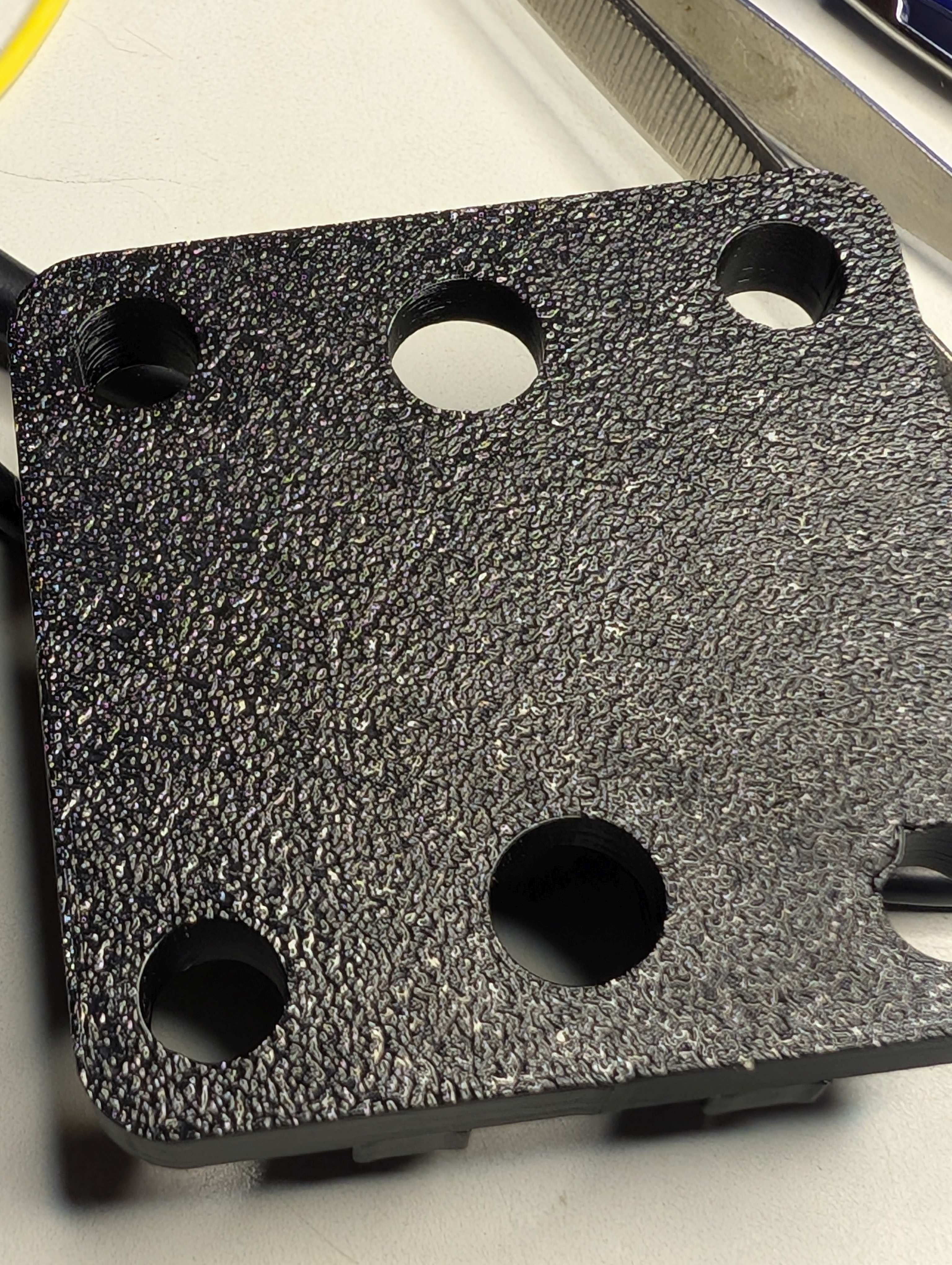

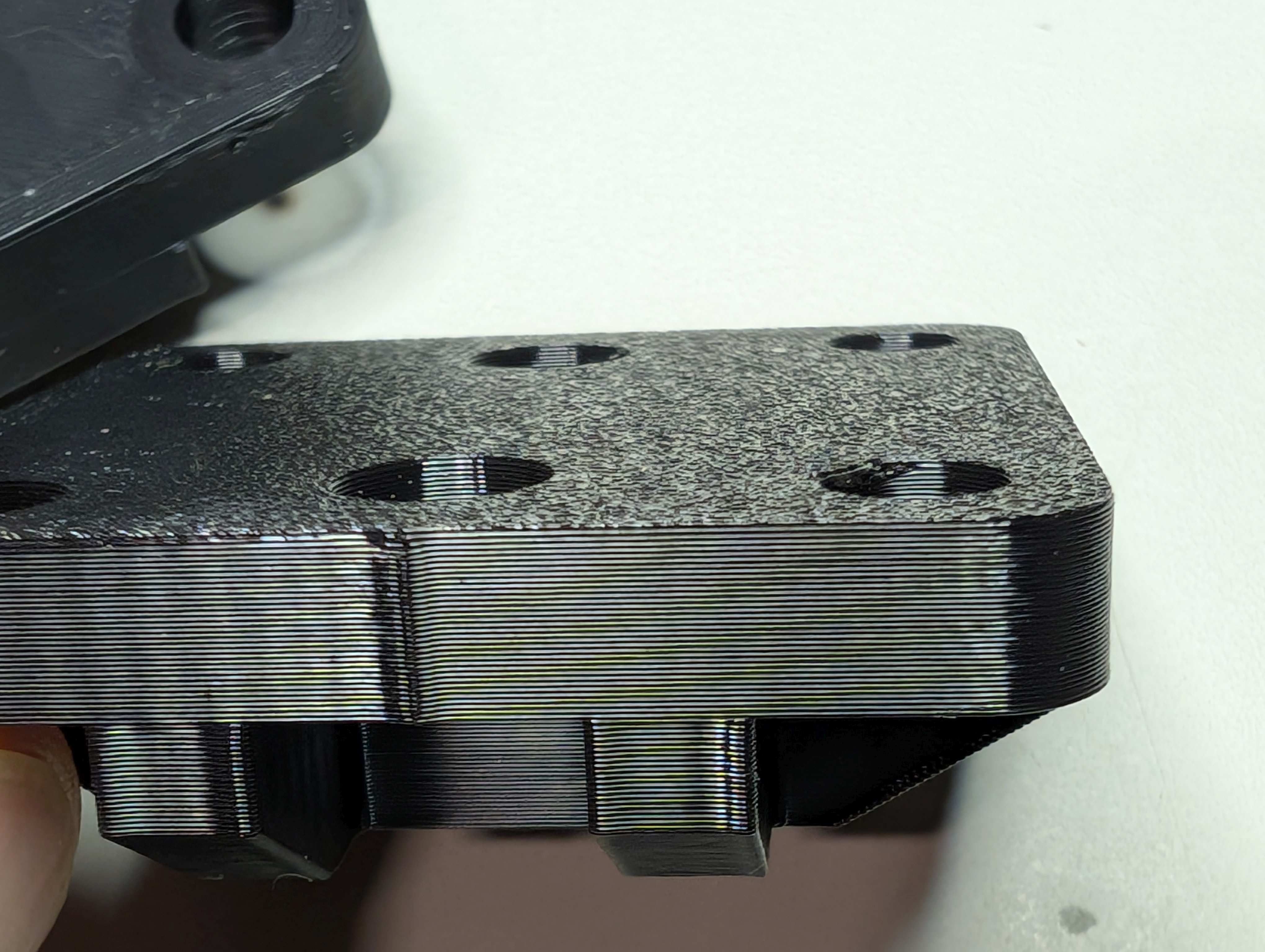

Printing the larger parts gives the impression that I'm almost done, but there is still a lot work to do...

I'm still waiting for the silicone foil, should arrive next week. BTW, has anyone tried to "mill" the silicone foil and graphite foil? I'm thinking to put it below a 2-3mm wood plate and use my OpenBuilds CNC router for it, wither with an engraving tool or a 4mm endmill... -

Printing the larger parts gives the impression that I'm almost done, but there is still a lot work to do...

I'm still waiting for the silicone foil, should arrive next week. BTW, has anyone tried to "mill" the silicone foil and graphite foil? I'm thinking to put it below a 2-3mm wood plate and use my OpenBuilds CNC router for it, wither with an engraving tool or a 4mm endmill...@czahl Thanks for sharing! Looking great so far! We usually cut the silicone gaskets either by hand or with a vinyl cutter (I used cricut for it),we've never tried something like what you're suggesting. Let us know how your approach goes!

-

BTW I love seeing everyone's different PP and PLA colors building very differently looking kits!

-

Printing the larger parts gives the impression that I'm almost done, but there is still a lot work to do...

I'm still waiting for the silicone foil, should arrive next week. BTW, has anyone tried to "mill" the silicone foil and graphite foil? I'm thinking to put it below a 2-3mm wood plate and use my OpenBuilds CNC router for it, wither with an engraving tool or a 4mm endmill...@czahl I haven't tried milling those materials but was considering similar options to what you have in mind. I'd give it a try at least, the more optoons we have, the better. And cutting gaskets will always be a thing in RFB production I'm afraid.

The alternative would be to simply get a drag knife like this: https://fr.aliexpress.com/item/1005006131524919.html

Also, congrats on printing the rest of you parts! They look very nice!

-

Yeah, nice work @czahl ! And another +1 for a drag knife being more appropriate than milling, but, it's worth giving it a go anyway! Laser cutter also possible, for gaskets, but no guarantee on the safety of fumes. IIRC cutting grafoil with a laser is possible only with a fiber laser, not CO2.

-

@kirk One question regarding the gasket. The upper surface of the printed parts is never as flat as the bottom, which is driven by the plate surface. Isn't it possible to wipe a small layer of usual silicone on it and let it dry? Optionally by immediately sticking the next part to assemble to it (e.g. membrane frame onto the flow frame)?

-

This is possible, but we haven't tried. We've been able to seal it with silicone gaskets so there's been no need. Also, if one of the gaskets gets damaged, it's simple to replace, unlike resealing the flow frame. But there's no reason you can't try!

"Ironing" the top layer of the print in your slicer may also make it smoother, or manually sanding, but again we haven't found it necessary to try this

-

@kirk One question regarding the gasket. The upper surface of the printed parts is never as flat as the bottom, which is driven by the plate surface. Isn't it possible to wipe a small layer of usual silicone on it and let it dry? Optionally by immediately sticking the next part to assemble to it (e.g. membrane frame onto the flow frame)?

@czahl I am a huge fan of trying this, especially for the larger format where setups are likely to be more permanent. As kirk mentioned we have never actually tried it, so please let us know if you do!