My build (very slowly progressing)

-

I got around printing the PP parts and it's not going great I'm afraid. The parts either don't stick (on PEI plate) or stick too much on PP tape. Even adding a layer of mineral oil doesn't help too much. The tape itself is also not very even due to bubbles. The top is also not super smooth. Who knows, maybe the gasket can seal anyways.

On the plus side, the electrolyte containers seem to be good.

Now I need to be patient about the Pumps from Kamoer which have't shipped yet and the Potentiostat wich also isn't completed yet.

I'm more and more considering printing my own centrifugal pump with magnetic coupling. This could also be interesting for the larger models as good pumps seem to be pretty expensive.

@danielfp248 said in My build (very slowly progressing):

@kirk Thanks for clarifying kirk, I have the same issue, lol.

I have added a note to the docs on this now!

Also @sepi I somehow missed reading the main chunk of your thread that you posted several days ago - great work!!

@sepi said in My build (very slowly progressing):

Now I need to be patient about the Pumps from Kamoer which have't shipped yet

@quinnale has also tried some 3D-printed peristaltic pumps in his build thread: https://fbrc.nodebb.com/topic/23/towards-a-working-system

@sepi said in My build (very slowly progressing):

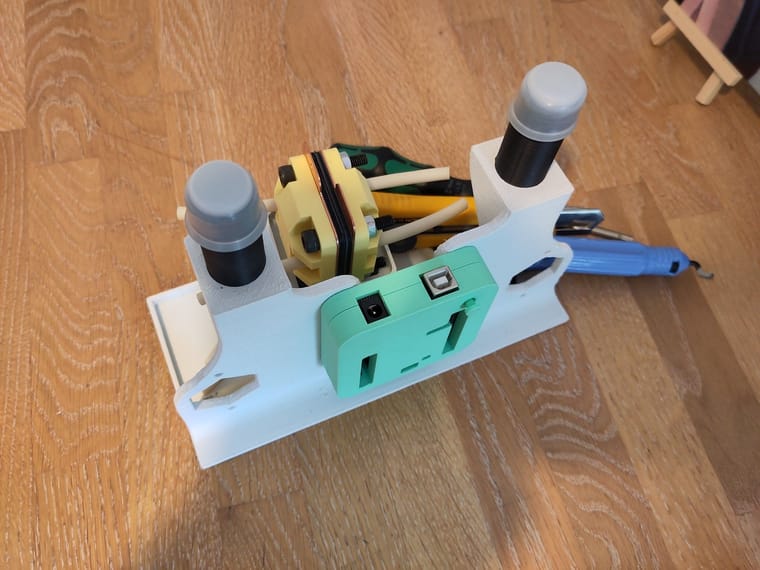

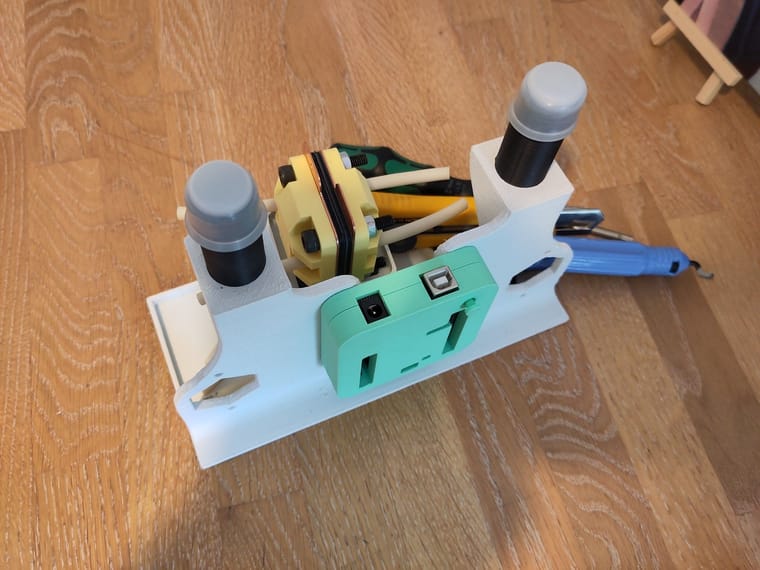

So I finally printed my modified jig in 6h on my kobra max with 1mm nozzle. This made it quick but fugly. You judge for yourself and maybe tell me why my modifications don't make sense.

Can you show the back of your jig? If the rear support doesn't stick out long enough, the entire jig can tip over once the pumps are installed due to a shift in the center of gravity.

Also, it looks cool and wavy! And using a lot less material. Did you modify it in FreeCAD?

-

I got around printing the PP parts and it's not going great I'm afraid. The parts either don't stick (on PEI plate) or stick too much on PP tape. Even adding a layer of mineral oil doesn't help too much. The tape itself is also not very even due to bubbles. The top is also not super smooth. Who knows, maybe the gasket can seal anyways.

On the plus side, the electrolyte containers seem to be good.

Now I need to be patient about the Pumps from Kamoer which have't shipped yet and the Potentiostat wich also isn't completed yet.

I'm more and more considering printing my own centrifugal pump with magnetic coupling. This could also be interesting for the larger models as good pumps seem to be pretty expensive.

@sepi said in My build (very slowly progressing):

I'm more and more considering printing my own centrifugal pump with magnetic coupling. This could also be interesting for the larger models as good pumps seem to be pretty expensive.

If you do, please share the results! This may be very demanding of PP FDM printing (leaktightness, tolerances, etc.). For reference, these are the pumps we are planning on using for the large-format cell (they are likely too large, but the smallest PP, mag drive centrifugal pumps we could find): https://fbrc.nodebb.com/post/30. They were less than 50 EUR each at a quantity of 2 pumps, IIRC.

-

@sepi said in My build (very slowly progressing):

I'm more and more considering printing my own centrifugal pump with magnetic coupling. This could also be interesting for the larger models as good pumps seem to be pretty expensive.

If you do, please share the results! This may be very demanding of PP FDM printing (leaktightness, tolerances, etc.). For reference, these are the pumps we are planning on using for the large-format cell (they are likely too large, but the smallest PP, mag drive centrifugal pumps we could find): https://fbrc.nodebb.com/post/30. They were less than 50 EUR each at a quantity of 2 pumps, IIRC.

-

@sepi said in My build (very slowly progressing):

The button does not work, it's just a tiny bit short. Maybe because my UNO is super old and used a different button.

FYI, that button is upside down which is why it doesn't work! You assemble it so that the large end is fixed inside the case (a bit of a balancing act during the assembly). The original designer has some photos of it assembled here: https://www.thingiverse.com/thing:628929

-

@danielfp248 said in My build (very slowly progressing):

@kirk Thanks for clarifying kirk, I have the same issue, lol.

I have added a note to the docs on this now!

Also @sepi I somehow missed reading the main chunk of your thread that you posted several days ago - great work!!

@sepi said in My build (very slowly progressing):

Now I need to be patient about the Pumps from Kamoer which have't shipped yet

@quinnale has also tried some 3D-printed peristaltic pumps in his build thread: https://fbrc.nodebb.com/topic/23/towards-a-working-system

@sepi said in My build (very slowly progressing):

So I finally printed my modified jig in 6h on my kobra max with 1mm nozzle. This made it quick but fugly. You judge for yourself and maybe tell me why my modifications don't make sense.

Can you show the back of your jig? If the rear support doesn't stick out long enough, the entire jig can tip over once the pumps are installed due to a shift in the center of gravity.

Also, it looks cool and wavy! And using a lot less material. Did you modify it in FreeCAD?

-

@kirk about the jig, yeah I modified the FreeCAD version. It's probably prone to tipping. I'll see that once I get the pumps and hobo modify it and then modify my model and share it.

-

@sepi Great job, your assembly is really looking quite good. Can't wait to see how it will perform.

-

@czahl said in My build (very slowly progressing):

@sepi Your PP parts are looking good. Which filament did you used?

https://www.3djake.com/fiberlogy/r-pp-anthracite?sai=12757

It's pretty soft but that might just be PP. I never used PP before. I just selected the cheapest one on 3dJake. -

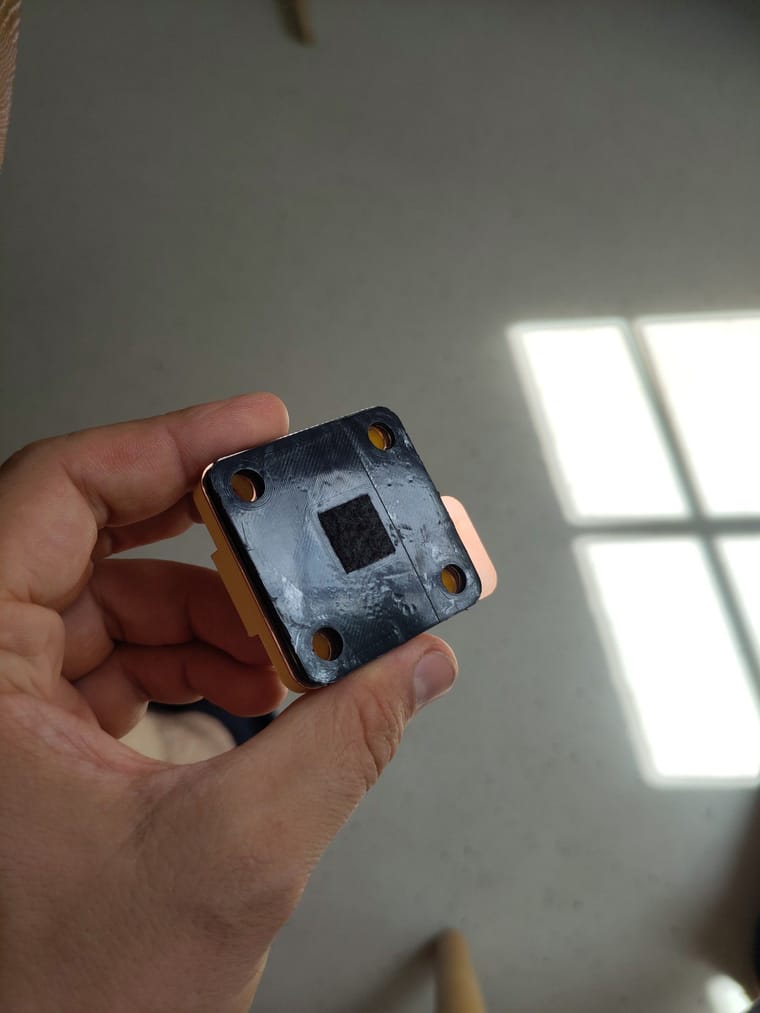

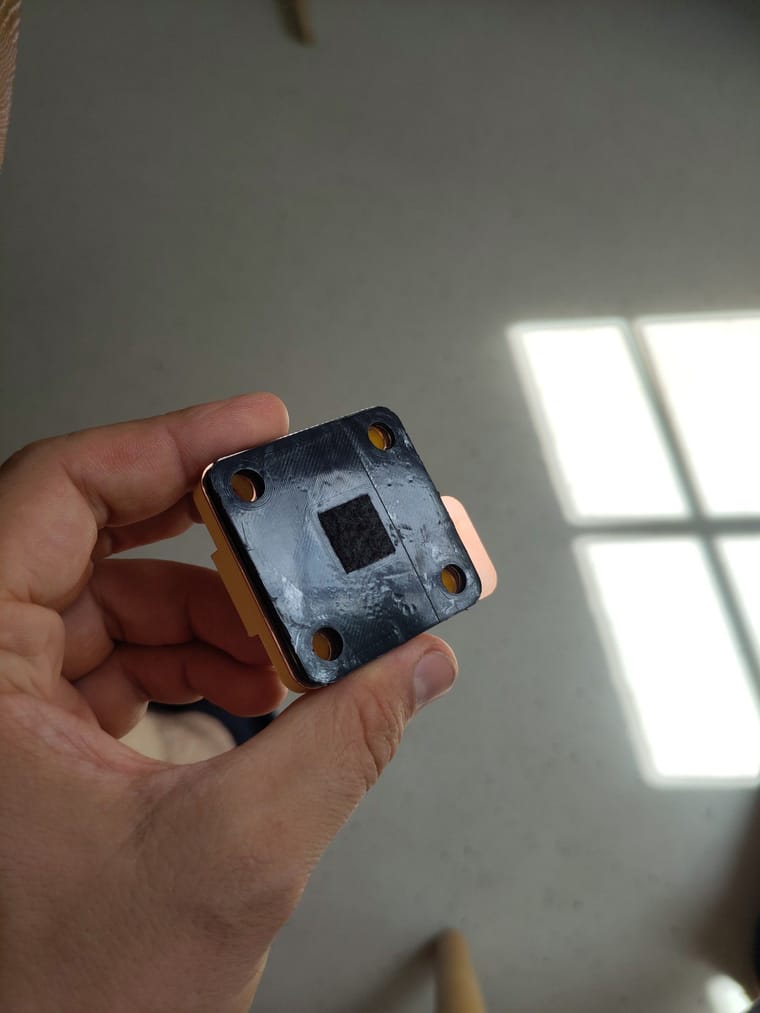

@sepi Nicely done! Also don't forget to wrap your screws in packing tape before you assemble the device for testing, otherwise the screws will short the cell.

-

@kirk about the jig, yeah I modified the FreeCAD version. It's probably prone to tipping. I'll see that once I get the pumps and hobo modify it and then modify my model and share it.

-

I've done it with just one flow frame: That seemed to be good. The problem with your proposal is that (at least that's what I think it is) the photo paper is permeable to air. I might put a piece of tubing on the second flow frame to test the seal on the whole cell. Then again, the only real test is to use some liquid. For that I need to wait for those pumps to arrive, which should be this or next week.

-

@sepi Nicely done! Also don't forget to wrap your screws in packing tape before you assemble the device for testing, otherwise the screws will short the cell.

@danielfp248 I actually used Kapton Tape but should probably use PP-tape instead.

-

I've done it with just one flow frame: That seemed to be good. The problem with your proposal is that (at least that's what I think it is) the photo paper is permeable to air. I might put a piece of tubing on the second flow frame to test the seal on the whole cell. Then again, the only real test is to use some liquid. For that I need to wait for those pumps to arrive, which should be this or next week.

@sepi said in My build (very slowly progressing):

I've done it with just one flow frame: That seemed to be good.

This sounds great. I also want to do the same then to eliminate as much of uncertainties as possible from the very beginning. It is always frustrating to identify such bugs after assembling everything together. For sure, the final test is the one with the liquids. Looking forward for your first tests with the pumps installed.

-

I've done it with just one flow frame: That seemed to be good. The problem with your proposal is that (at least that's what I think it is) the photo paper is permeable to air. I might put a piece of tubing on the second flow frame to test the seal on the whole cell. Then again, the only real test is to use some liquid. For that I need to wait for those pumps to arrive, which should be this or next week.

@sepi If you have an assembled cell with everything except the pumps you can use a syringe to manually pump some liquid through and see if you have any obvious leaks. This is how I normally test cells before I put activate material inside them or cycle water through them using pumps.

-

@sepi If you have an assembled cell with everything except the pumps you can use a syringe to manually pump some liquid through and see if you have any obvious leaks. This is how I normally test cells before I put activate material inside them or cycle water through them using pumps.

@danielfp248 Good trick, now I only need a syringe.

-

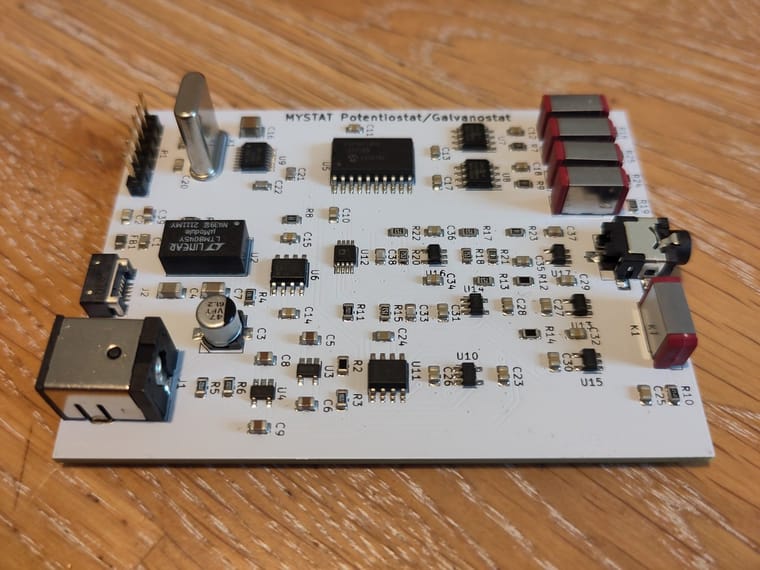

My Mystat finally arrived, yay! No I need to figure out how to flash that pic (hopefully no programmer neede) and get rid of the remaining 5 PCBs.

@sepi You do need a programmer to flash that. We use a PcKit3 programmer.

-

@danielfp248 noooooooooooo. I'll add: replacing it with an esp32, to the list of projects I will never do.

-

@danielfp248 noooooooooooo. I'll add: replacing it with an esp32, to the list of projects I will never do.

-

Yay, I got my MyStat working (a least to some extent). After fiddeling a bit with the yucky Microchip ISP software of which I had to install an outdated version (3.20 afaik) because they removed PicKit3 support, I finally managed to program Kirk's firmware on the device. Getting to run the python host software was fortunately pretty easy.

At first I was a bit stumped by an error message about an out of range current which I tried to calibrate away. It only occurred to me a bit later to connect the main PSU, which corrected the issue

Unfortunately I have some issues with commands that don't go through like the one for saving calibration to the device returning '?' instead of 'OK'.

Any Idea @kirk ?