Hi everyone,

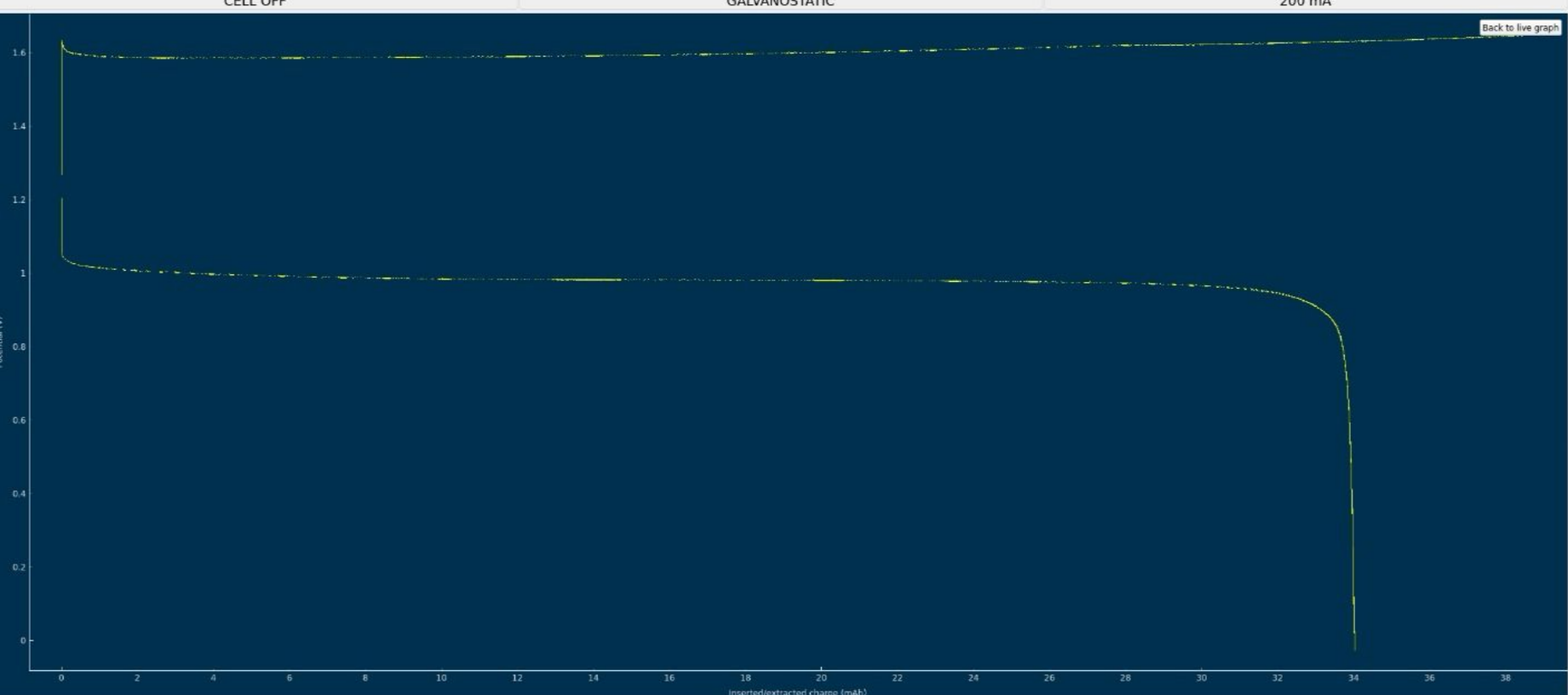

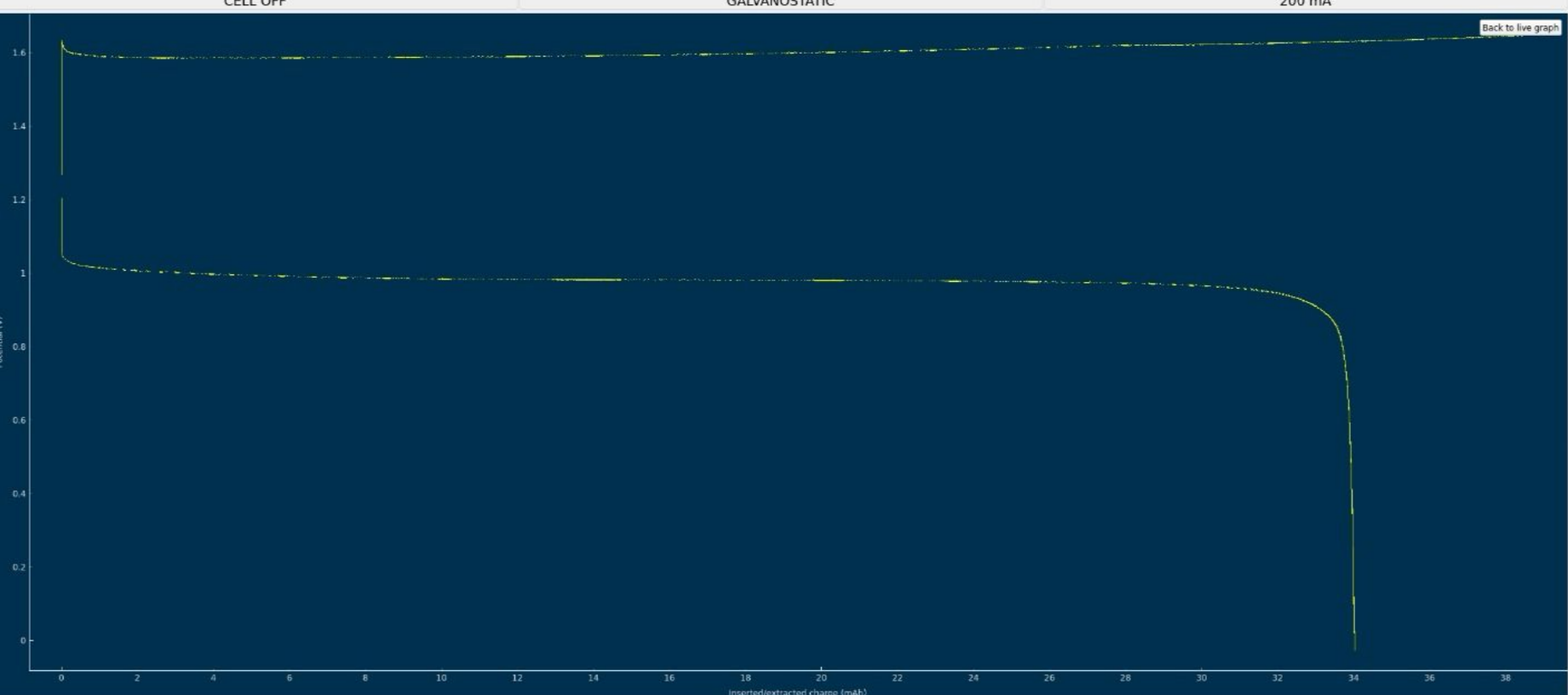

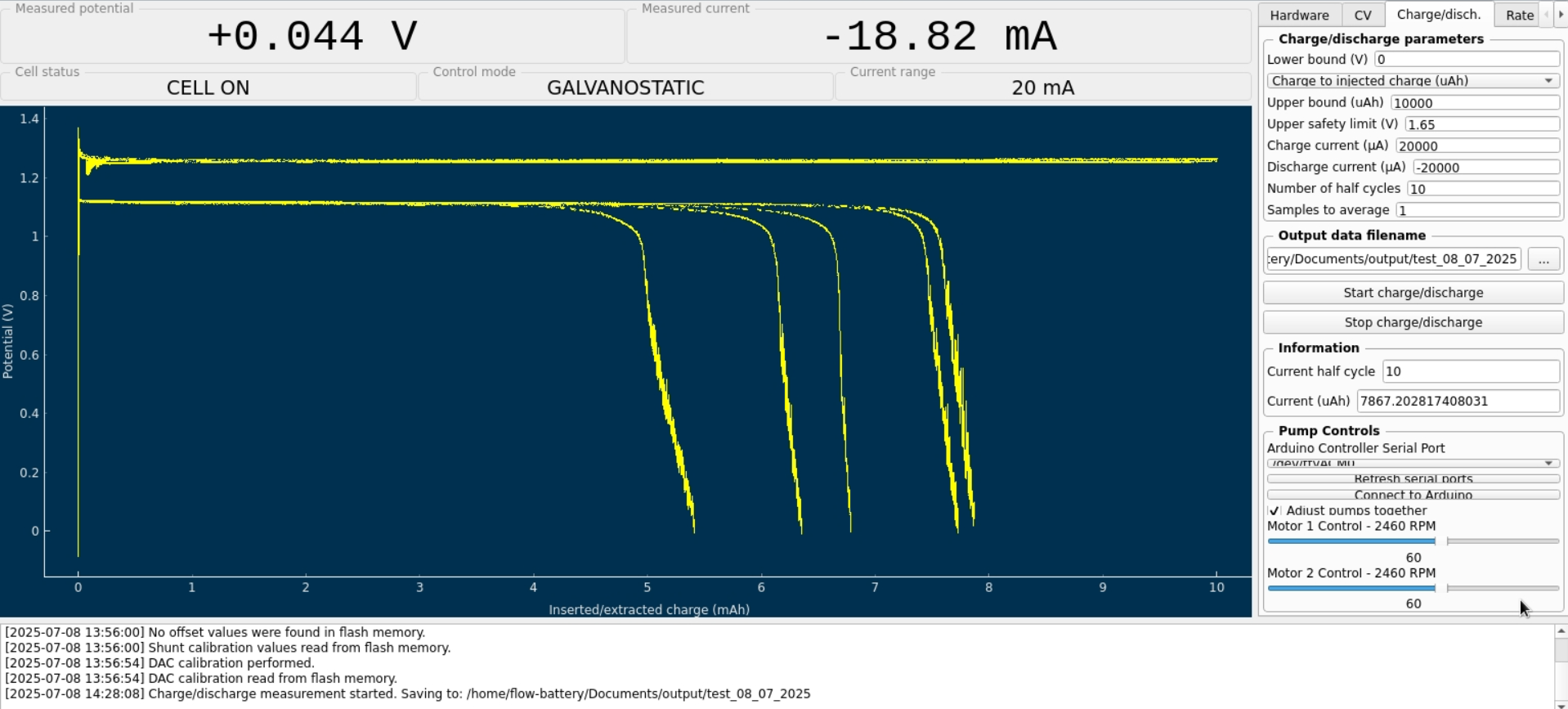

Over the past few months I've started tests multiple times. In some cases, leaks appeared within the first 5 charge cycles when charging to 10 mAh at 20 mA. However, if the system was leak-free at the beginning, it would usually survive the subsequent charge cycles as well. Unfortunately, I have never managed to reach 100 mAh while charging at 40 mA, following the guidelines you provided.

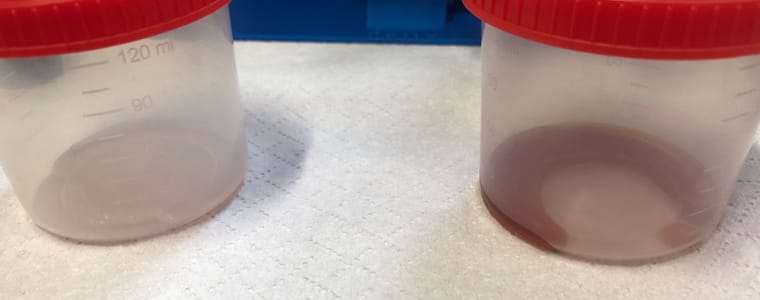

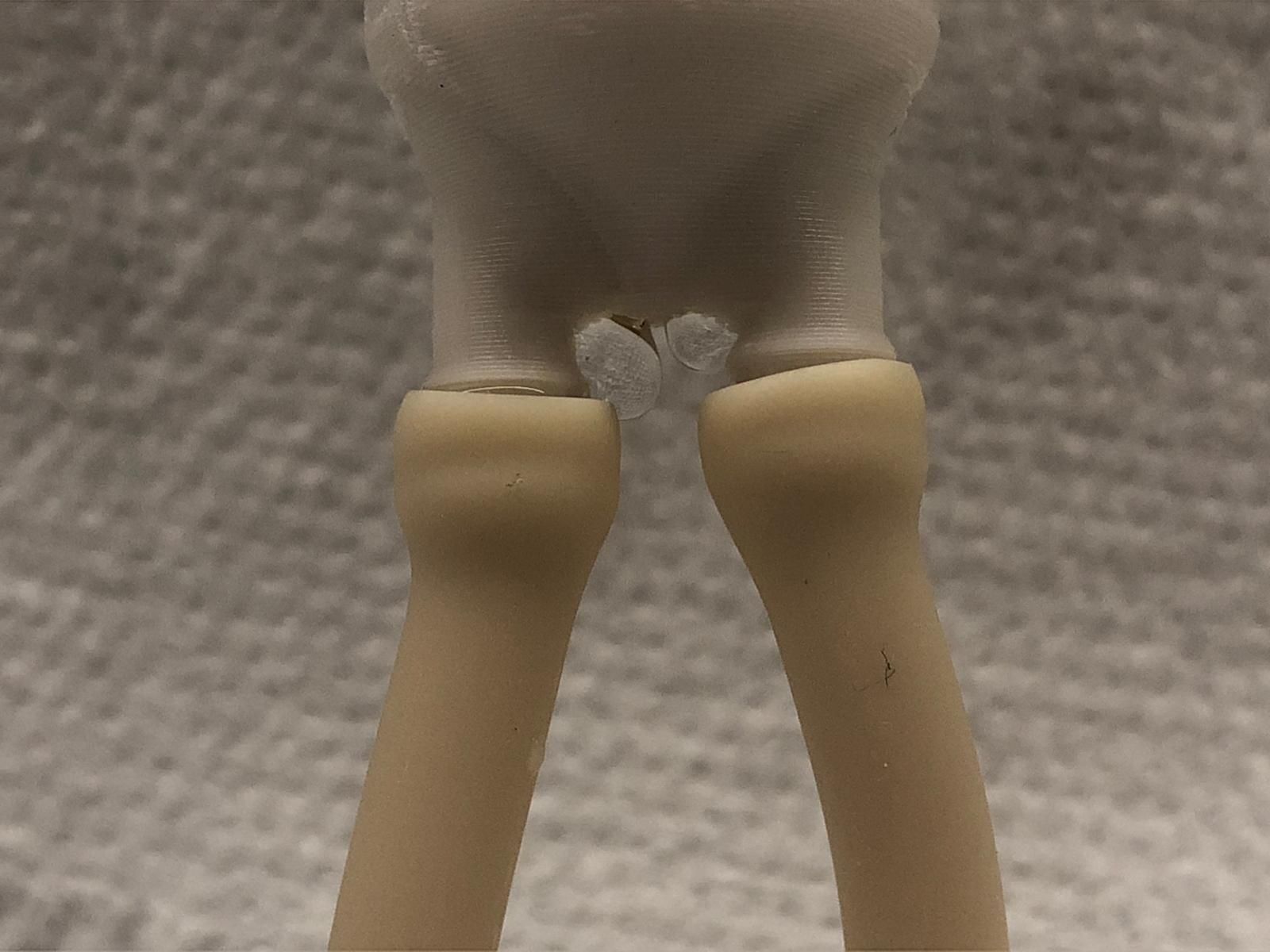

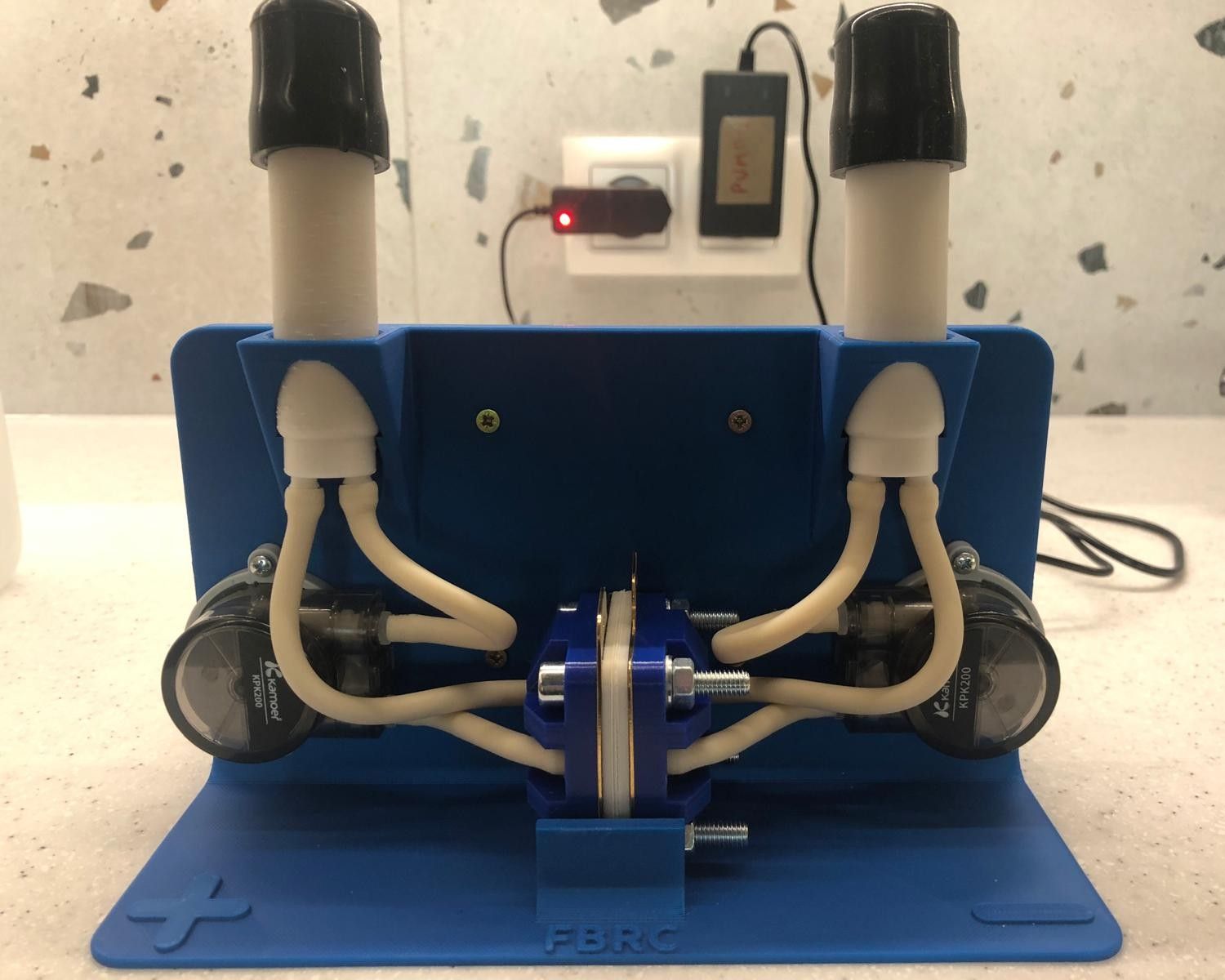

Each time, the voltage reached 1.65 V much earlier than expected (on average around 40 mAh). Leaks occurred frequently (tubing burst, the cell lost its seal, and once the electrolyte even suddenly leaked from the tanks(!)). On the voltage plots, these leaks showed up as sudden spikes or unstable/uneven charging voltage values. I suspect that something was often getting clogged in the system, causing a rapid pressure increase. I measured that Kamoer KPK200 pumps can generate over 0.4 MPa (!) of pressure when the outlet is blocked.

There were also attempts where I did not observe a visible leak — but even then, a one-off voltage disturbance still occurred. In those cases, the voltage began rising faster, and shortly after that it still hit 1.65 V, stopping the charge. My MyStat is calibrated, and I additionally verified the charging voltage with a multimeter to confirm it was definitely 1.65 V.

For most of my tests I used a membrane made of 3 layers of photo paper, as suggested by @kirk . Recently, I also tested a 4-layer photo paper membrane. In that setup, the charging voltage was immediately about 0.1 V higher, and it also reached 1.65 V at just under 40 mAh, stopping the charge.

I assume that in your setups you can repeatedly charge to 100 mAh at 40 mA without issues. And 100 mAh doesn’t seem like much when compared to the results in this publication https://www.nature.com/articles/ncomms7303 , where the authors reported 166.7 Wh/L. For an FBRC cell, that would correspond to roughly 1200 mAh, correct?

Do you have any advice for me? Where could the root cause of my failures be?

Am I definitely not supposed to use polypropylene felt on the catholyte side?

Could there be an issue with the material quality I'm using (even though everything was purchased according to the Bill of Materials sources)?

Pasting results from my latest run below — the 4-layer photo paper membrane test, charging current 40mA.